Introduction

Struggling to define “high-end” furniture beyond its price tag? This confusion can lead to costly mistakes. True luxury is about performance and precision, not just appearance.

High-end custom furniture is a complete system. It combines engineering-grade design[^1], stable and appropriate materials[^2], and a transparent, traceable manufacturing process. It’s not just about a luxury look; it’s about delivering long-term value[^3], consistency, and a perfect fit[^4] for a specific space and use.

I’ve seen many projects where the term “high-end” gets thrown around loosely. It often gets attached to anything with a big price or an exotic material. But after years of turning complex designs into reality for hotels and commercial spaces, I’ve learned that the real meaning is much deeper. It’s a disciplined approach that guarantees the final product doesn’t just look good on day one, but performs flawlessly for years to come. Let’s break down what this really involves.

Does high-end just mean expensive materials?

You see a stunning design using rare wood and imported marble. You assume it’s top quality because of the cost. But without the right engineering, those materials can fail.

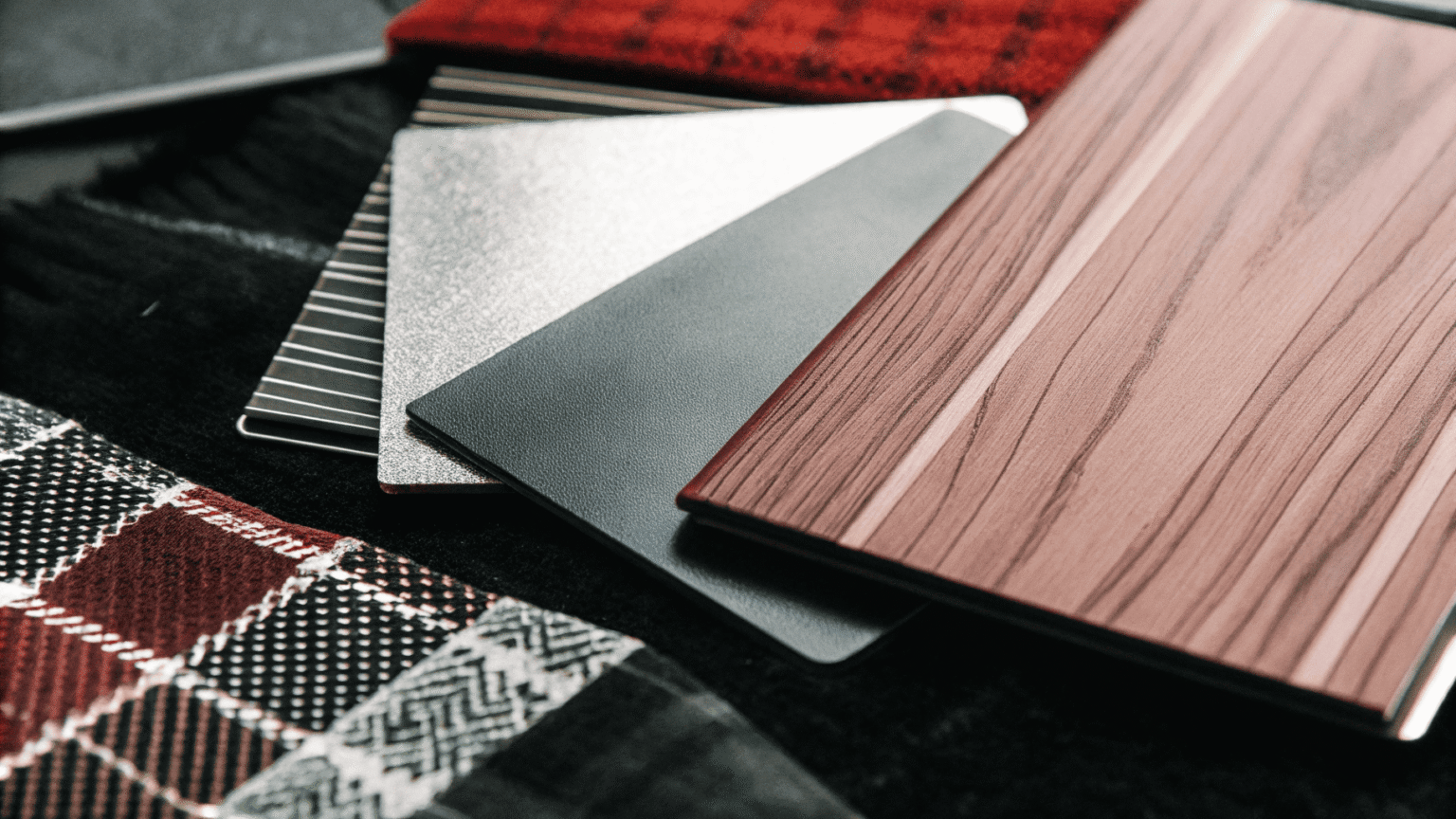

No, it’s about choosing the *right* materials for the job. High-end furniture balances aesthetics with stability, sustainability, and tactile quality. The focus is on long-term performance in a specific environment, like a high-traffic hotel lobby, not just on using the most expensive option available.

In my experience, material selection[^5] is a science. A beautiful solid wood might look amazing, but if it’s not properly kiln-dried and engineered for a humid climate, it will warp. That’s not a high-end outcome. We focus on a holistic view of materials, considering every aspect of their performance.

Material Stability is Key

For commercial projects, furniture is an asset that needs to last. Stability is non-negotiable. We don’t just pick a material; we specify its properties. For wood, this means ensuring the moisture content is perfect for the project’s destination. For metals, it means choosing the right grade and finish to prevent corrosion and wear. For upholstery, it means specifying commercial-grade fabrics[^6] with high rub counts that can withstand daily use. It’s this deep level of specification that separates professional work from simple decoration.

Beyond the Look: The Feel and Footprint

True high-end quality is also felt. It’s the smooth, durable finish on a tabletop, the satisfying weight of a metal handle, or the texture of a well-chosen fabric. We also consider the environmental impact. Sourcing sustainable materials[^7], like FSC-certified wood, and using low-VOC (volatile organic compound) finishes is now a standard part of high-end production. It’s about creating pieces that are not only beautiful and durable but also responsible.

Material Aspect | Standard Approach | High-End Approach |

Wood | Chooses based on look (e.g., “oak”) | Specifies kiln-dried solid wood or engineered veneer for climate stability. |

Metal | Basic steel with a simple powder coat | Specifies grade (e.g., 304 stainless steel) with PVD or durable finish. |

Fabric | Residential-grade, chosen for color | Commercial-grade, with specified rub count, fire rating, and cleanability. |

Finishes | Standard lacquer | Low-VOC, multi-layer finish tested for scratch and chemical resistance. |

Is it about the design or the engineering?

You have a brilliant design concept from an architect. But turning that vision into a functional, durable piece of furniture is a huge challenge. Without proper engineering, the design can fail.

It’s about both, working together perfectly. High-end customization uses engineering to make a creative vision a reality. The engineering process[^8] translates the design into a detailed manufacturing plan, ensuring the final piece is not only beautiful but also structurally sound and built to last.

I’ve received countless beautiful sketches that were, frankly, impossible to build as drawn. My job isn’t to say “no,” but to ask, “how can we engineer this to work?” The magic happens when we bridge the gap between the designer’s intent and the physical realities of manufacturing. This is where engineering becomes the most critical, yet unseen, part of high-end furniture.

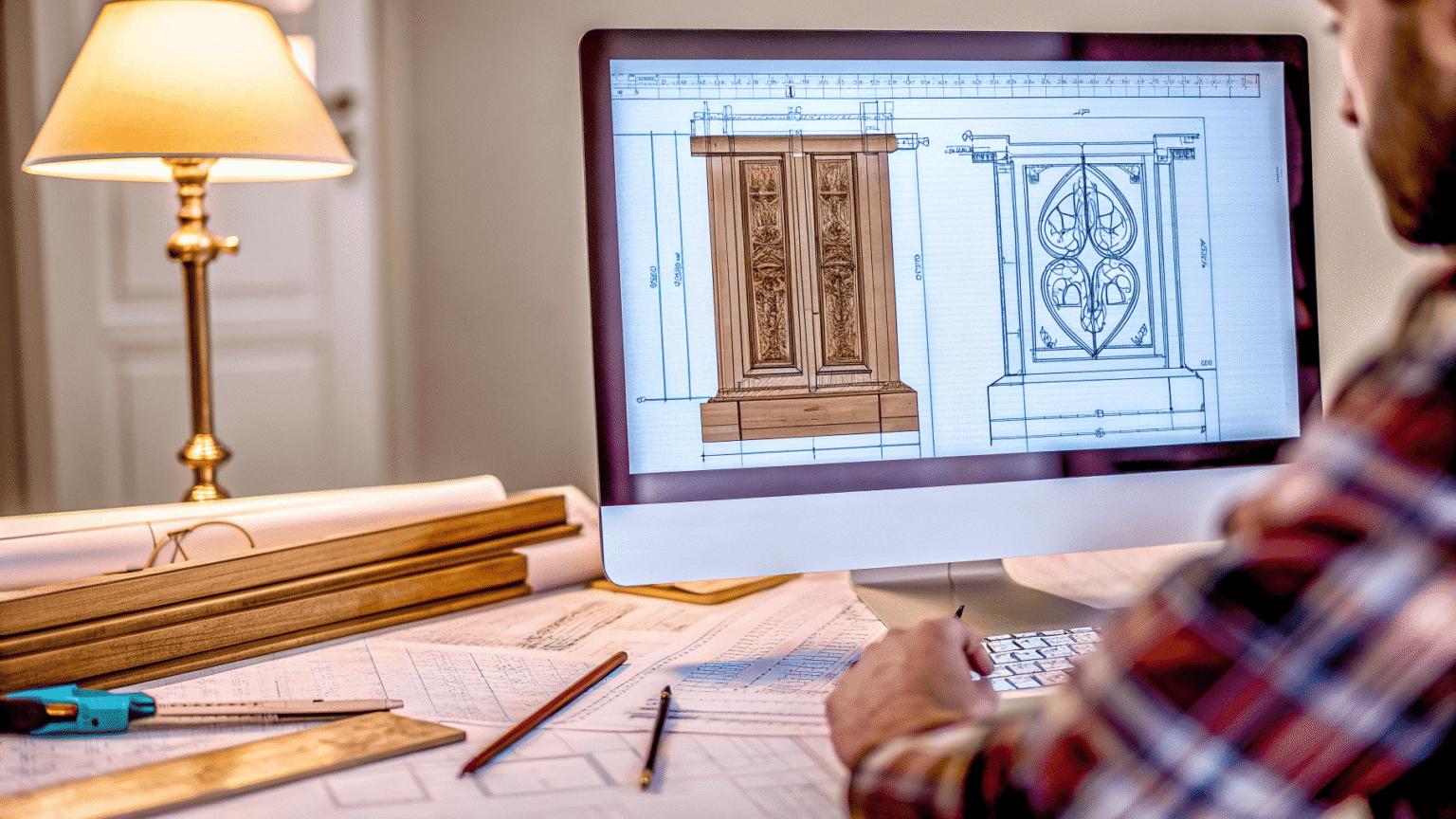

From Vision to Shop Drawings

The first step is creating detailed shop drawings[^9]. This is our blueprint. It goes far beyond a simple sketch. Our shop drawings specify every single detail: exact dimensions, joinery methods, material types, hardware, and finish codes. This process forces us to solve problems on paper before we cut a single piece of wood. It ensures that what the designer envisioned is precisely what we will produce, leaving no room for assumptions or errors. For complex pieces that integrate wood, metal, and stone, these drawings are essential for ensuring every component fits together perfectly.

The Unseen Details: Structure and Durability

A chair in a hotel lobby might be used hundreds of times a day. A standard chair wouldn’t last a month. Our engineering focuses on this kind of real-world use. We analyze stress points[^10] and reinforce the structure accordingly. We choose joinery techniques[^11]—like mortise and tenon joints instead of simple screws—that are designed for longevity. This commitment to unseen structural integrity is a core principle of high-end custom furniture[^12]. It’s the difference between a piece that just looks good and a piece that performs for a decade.

Process Stage | Designer’s Role | Our Engineering Role |

Concept | Provides the aesthetic vision, mood board, and sketches. | Provides initial feedback on feasibility and material options. |

Development | Refines the design based on feedback. | Creates detailed shop drawings, specifying all materials and construction. |

Sampling | Approves the physical prototype for look and feel. | Builds a sample to test ergonomics, durability, and finish quality. |

Production | Final sign-off. | Manages mass production based on the approved sample and drawings. |

How does process control define high-end furniture?

You’re managing a 200-room hotel project. Inconsistent finishes, mismatched pieces, and delays from multiple suppliers can turn your project into a nightmare. A lack of control creates chaos.

Process control is the backbone of high-end furniture manufacturing. It means total transparency, quality checks[^14] at every stage, and a unified system that guarantees every single piece, from the first to the last, is identical in quality. This is how we deliver consistency on complex projects.

For a large-scale project, the real challenge isn’t making one perfect piece; it’s making hundreds of perfect pieces. This is impossible without a rigid, documented process. Over the years, I’ve seen that the best suppliers aren’t just good at making furniture; they are masters of project management and quality control. This is why at NEXTOP, we built our entire system around a one-stop execution model[^15].

Why a Single System Matters

When you work with separate suppliers for furniture, metalwork, and upholstery, you’re asking for trouble. Finishes won’t match, timelines will conflict, and accountability becomes a blame game. By handling everything—engineering, sampling, production for both furniture and metal, QC, and logistics—under one coordinated system, we eliminate these risks. A metal base for a table is made in tandem with the wooden top, ensuring a perfect fit[^4] and finish. There is one point of contact and one source of truth, which simplifies communication and ensures a smooth workflow for our clients.

Transparency and Traceability

A high-end process is one you can see. We provide our clients with clear photo and video reports at every key stage of production. From raw material inspection to final packaging, you see your project coming to life. This transparency builds confidence and allows for course correction if needed. Each step is documented, creating a traceable record of quality. This isn’t just about making furniture; it’s about manufacturing confidence and delivering peace of mind. That systematic reliability is the ultimate luxury.

True high-end custom furniture[^12] is a service, not just a product. It’s an engineered system delivering consistent quality, long-term value[^3], and a perfect reflection of your design vision.

[1]: Learn how engineering-grade design enhances the durability and functionality of furniture.

[2]: Discover the importance of material selection in creating high-end furniture that lasts.

[3]: Find out how high-end furniture is an investment that pays off over time.

[4]: Learn the techniques used to ensure custom furniture fits perfectly in its intended space.

[5]: Delve into the science of material selection and its impact on furniture performance.

[6]: Learn why commercial-grade fabrics are essential for durability in high-traffic areas.

[7]: Explore the role of sustainable materials in creating responsible and eco-friendly furniture.

[8]: Understand how the engineering process transforms design concepts into functional furniture.

[9]: Discover how detailed shop drawings ensure precision and accuracy in furniture production.

[10]: Discover how analyzing stress points contributes to the durability of furniture.

[11]: Learn about joinery techniques that enhance the longevity and strength of furniture.

[12]: Explore the nuances of high-end custom furniture and understand its true value beyond just price.

[13]: Find out how process control ensures consistent quality in high-end furniture manufacturing.

[14]: Explore the importance of quality checks in maintaining high standards in furniture.

[15]: Learn how a one-stop execution model simplifies the furniture production process.