Introduction

Struggling to find a durable, modern material for your project’s landmark? The weather and maintenance costs can ruin a great design. I’ve seen it happen many times.

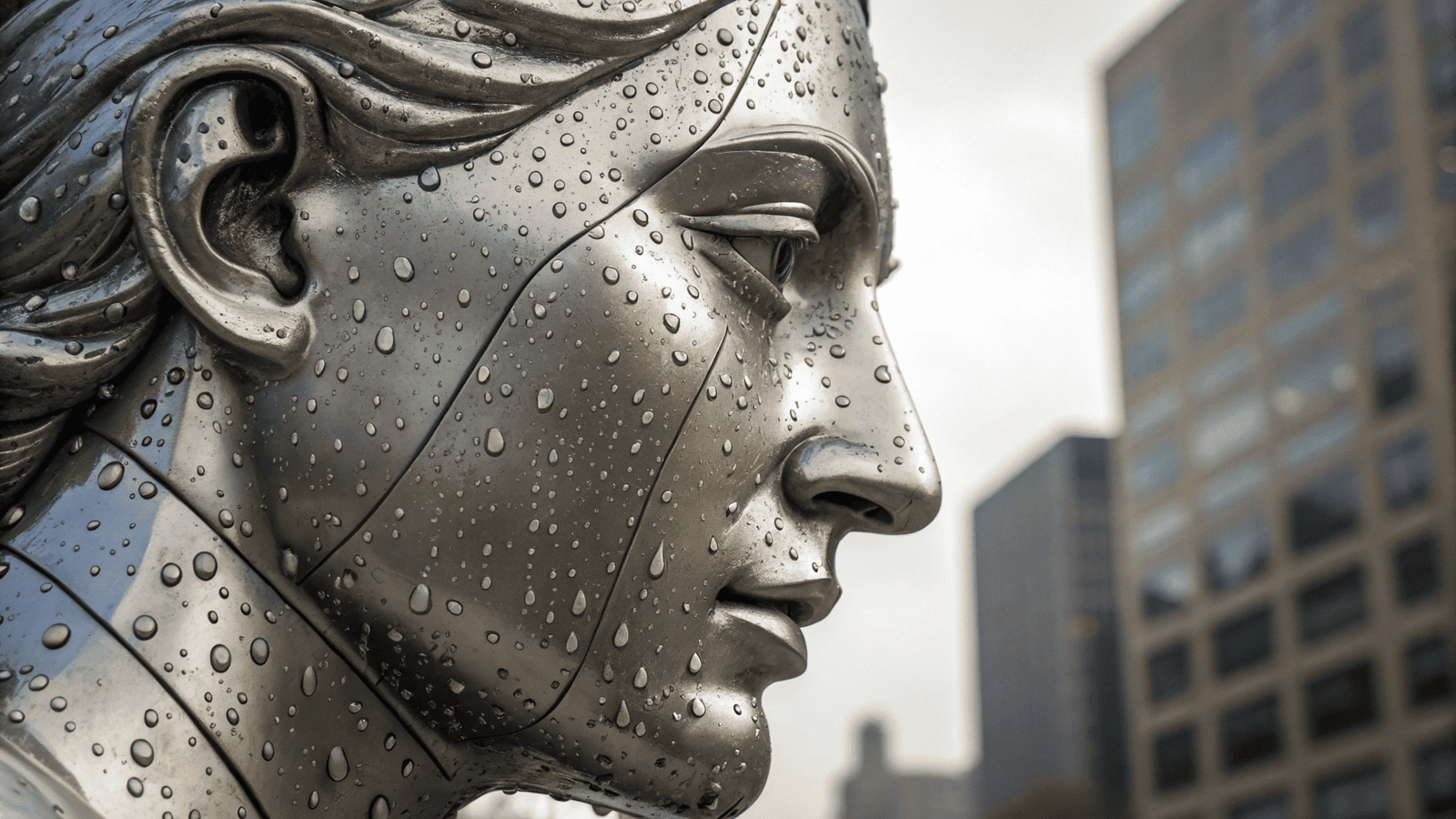

Stainless steel sculpture[^1] offers superior durability and design flexibility[^2]. Its resistance to corrosion[^3] and weather reduces long-term maintenance costs[^4], while its malleability[^5] allows for stunning, complex shapes perfect for iconic public art[^6].

This material is a top choice for so many architects and designers for a reason. But the benefits go beyond just looking good. From my experience managing these complex fabrications, the real advantages are in the performance and project execution. Let’s break down why this material consistently delivers value, from the first sketch to years after installation.

Why is Stainless Steel So Durable for Outdoor Art?

Worried your outdoor sculpture will rust or degrade over time? Coastal air and harsh sun can be brutal on materials. I know this is a major concern for clients investing in public art[^6].

Stainless steel contains chromium, which forms a passive, self-healing layer on the surface that resists rust and corrosion. This makes it ideal for outdoor installations, even in harsh coastal or industrial environments, ensuring longevity with minimal upkeep.

The long-term stability of an outdoor installation is not just about looks; it’s about protecting the investment. I’ve seen projects where other materials start showing wear and tear within a few years, leading to costly repairs. Stainless steel avoids this problem because of its fundamental chemical makeup[^7]. It’s not just a coating; the resistance is part of the metal itself. This is especially critical for projects in humid climates[^8] or coastal cities where salt in the air accelerates corrosion. The right grade of stainless steel, like 316L, is specifically chosen for these challenging environments. This built-in durability means the sculpture will maintain its structural integrity and surface finish for well over a decade with very simple cleaning, which is a huge advantage for my clients who manage large properties and need predictable, low maintenance costs.

Comparing Material Durability

Material | Corrosion Resistance | Maintenance Needs | Ideal Environment |

Stainless Steel | Excellent | Low (Periodic Cleaning) | All, including coastal/industrial |

Bronze | Good (Patina Forms) | Medium (Waxing/Cleaning) | Most, but can stain surfaces |

Corten Steel | Forms a rust-like layer | Low (After initial period) | Non-coastal, away from surfaces |

Painted Steel | Dependant on coating | High (Repainting/Touch-ups) | Mild, controlled environments |

How Does Stainless Steel Allow for Creative Freedom in Design?

Is your design vision being limited by traditional materials? Complex curves and massive, seamless forms can be very difficult to achieve with stone or wood. I’ve faced this challenge with many design teams.

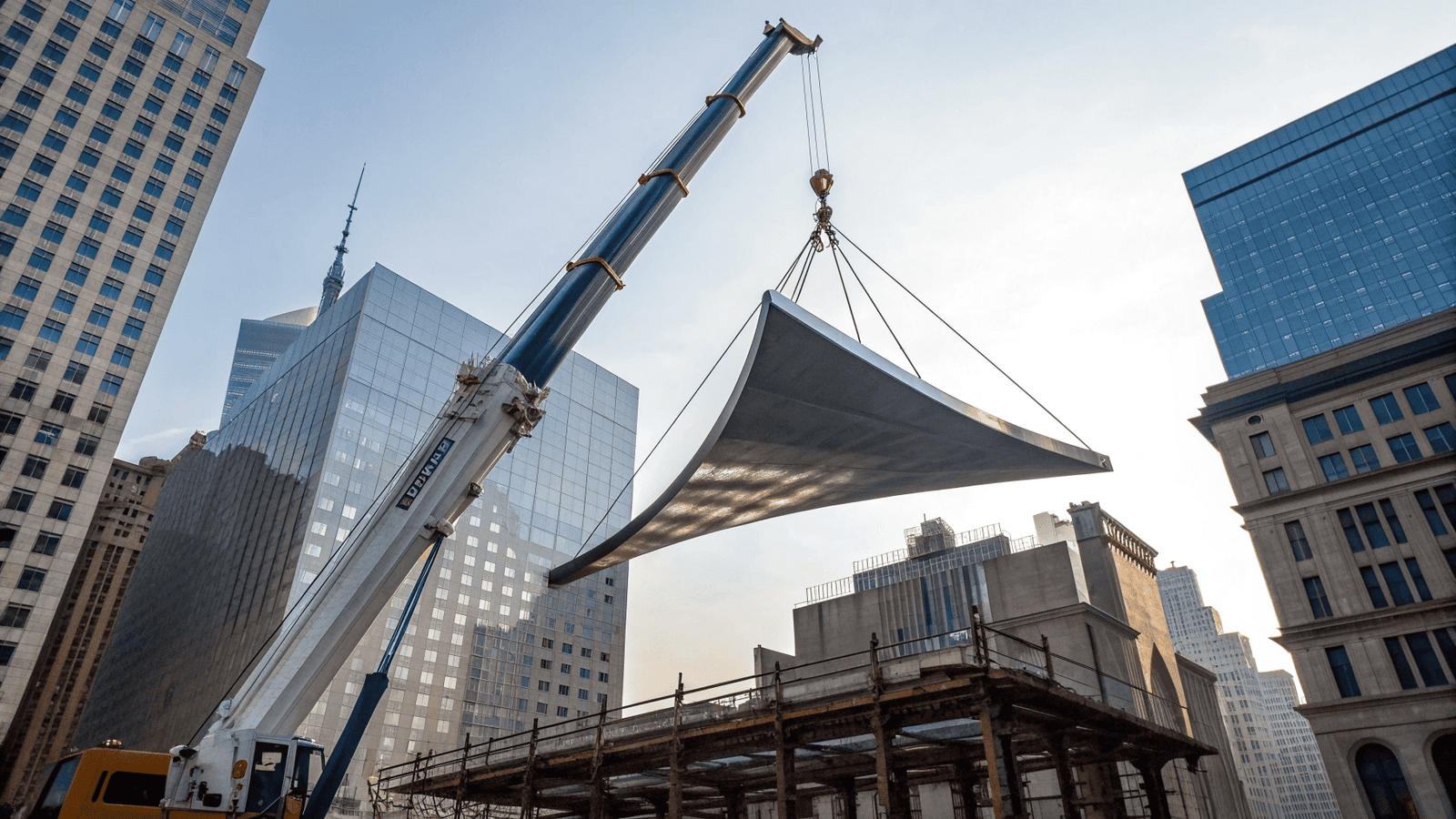

The excellent ductility[^9] of stainless steel allows it to be shaped into complex, fluid forms and large-scale structures that are impossible with stone or glass. This makes it perfect for creating the bold, contemporary, and iconic landmark sculptures[^10] that clients want.

When an architect brings me a design for a landmark piece, they are often looking for something that feels both monumental and graceful. Stainless steel is the key to making that happen. We can take flat sheets of metal and, through processes like rolling, pressing, and welding, create enormous, flowing shapes that appear almost weightless. The seams can be welded and polished until they are completely invisible, giving the final sculpture a single, unified form. This is a huge advantage over materials like stone, which is subtractive and limited by the size of the block. With stainless steel, the scale is virtually unlimited. In my factory, we’ve engineered massive, curved panels that come together to form towering structures. This flexibility is why stainless steel has become the go-to material for the signature art pieces that define modern buildings and public spaces.

Achieving Different Looks with Surface Finishes

Finish Type | Visual Effect | Best For |

Mirror Polish | Highly reflective, mirror-like | Blending with surroundings, dynamic reflections |

Brushed/Satin | Soft, linear grain, low reflectivity | Hiding fingerprints, modern architectural look |

Matte/Bead Blasted | Non-reflective, uniform, soft | Subtle, minimalist designs |

Colored (PVD) | Gold, black, bronze tones | Adding color without paint, luxury feel |

What Makes Stainless Steel a Practical Choice for Large Projects?

Managing a large-scale project with a tight deadline? Coordinating multiple suppliers for materials, fabrication, and installation is a huge risk. I know the stress it causes project managers and developers.

Stainless steel is relatively lightweight compared to stone, which simplifies transportation and installation. Its high strength-to-weight ratio[^11] allows for safer, more flexible installation methods[^12], making it highly advantageous for large, time-sensitive commercial and public projects.

On a recent hotel project, we had to install a 30-foot sculpture in a central courtyard with limited crane access. If it had been made of solid stone, the weight would have made the installation nearly impossible and extremely expensive. Because we used a stainless steel structure, the piece was much lighter. We could engineer it in sections that were easier to transport and lift into place. This control over logistics is a massive, often overlooked, advantage. It reduces risks on-site, speeds up the installation timeline, and ultimately saves the project money. In our one-stop system at NEXTOP, we handle the engineering, fabrication, and delivery coordination together. This means we can plan the entire process, from how a piece is built to how it will be lifted off the truck, ensuring a smooth and predictable delivery for projects with tight schedules.

Project Risk Control: Stainless Steel vs. Traditional Materials

Factor | Stainless Steel | Stone / Glass | Advantage |

Transportation | Lower weight, less risk of damage | Very heavy, high risk of cracking/chipping | Stainless Steel |

Installation | Faster, requires lighter equipment | Slow, requires heavy-duty cranes | Stainless Steel |

On-site Safety | More manageable sections | Risk of catastrophic failure if dropped | Stainless Steel |

Schedule Impact | Predictable, less weather-dependent | Can be delayed by logistical challenges | Stainless Steel |

How Does the Cost of Stainless Steel Sculpture Compare Over Time?

Is the initial cost of stainless steel holding you back? It’s easy to focus on the upfront price tag. But I always advise my clients to look at the total cost of ownership[^13].

While the initial investment for stainless steel might seem higher than some materials, its long-term value[^14] is exceptional. The minimal maintenance, cleaning, and repair needs result in a significantly lower total cost over the sculpture’s lifespan.

I often talk with clients who are comparing the initial quotes for a sculpture made from different materials. Yes, painted steel might be cheaper upfront. But I ask them to consider the costs five or ten years down the road. That painted sculpture will need to be stripped and repainted multiple times to prevent rust and keep it looking good. A bronze piece might need regular, specialized waxing. A stainless steel sculpture, however, just needs occasional cleaning with soap and water to maintain its original appearance for decades. When you add up all those future maintenance costs and labor, the stainless steel option is almost always the more economical choice. It provides budget certainty[^15] for property owners and ensures the commercial and aesthetic value of the artwork endures. It’s not just buying a sculpture; it’s making a smart, long-term investment in the property.

Calculating the Total Cost of Ownership (TCO) - 20 Year Estimate

Material | Initial Cost | Est. Maintenance Cost (20 Yrs) | Total Cost of Ownership |

Stainless Steel | High | Low ($2,000) | High |

Bronze | Very High | Medium ($10,000) | Very High |

Painted Steel | Medium | High ($25,000+) | Medium-High |

Conclusion

In short, stainless steel offers a powerful mix of lasting beauty, design freedom, and smart long-term costs. It is a reliable and valuable choice for any landmark project.

[^1]: Explore the advantages of stainless steel sculptures, including durability and design flexibility, for your next project.

[^2]: Learn how these factors influence the selection of materials for iconic architectural designs.

[^3]: Discover materials that resist corrosion effectively, ensuring longevity for outdoor art and structures.

[^4]: Understand the importance of considering maintenance costs in your project budget for better financial planning.

[^5]: Find out how malleability allows for innovative and complex designs in sculpture making.

[^6]: Stay updated on the latest trends in public art and how materials like stainless steel are shaping them.

[^7]: Explore how the chemical properties of materials contribute to their performance and longevity.

[^8]: Learn about materials that withstand humid conditions, ensuring the durability of outdoor installations.

[^9]: Understand the role of ductility in allowing for innovative and complex sculpture designs.

[^10]: Discover the elements that contribute to a sculpture’s status as an iconic landmark in public spaces.

[^11]: Discover how a high strength-to-weight ratio can improve safety and efficiency in construction projects.

[^12]: Find out effective installation methods that ensure safety and efficiency for large sculptures.

[^13]: Learn how to assess the total cost of ownership to make informed decisions for art projects.

[^14]: Understand the key factors that enhance the long-term value of public art installations.

[^15]: Explore strategies to ensure budget certainty in your art projects for better financial management.