Introduction

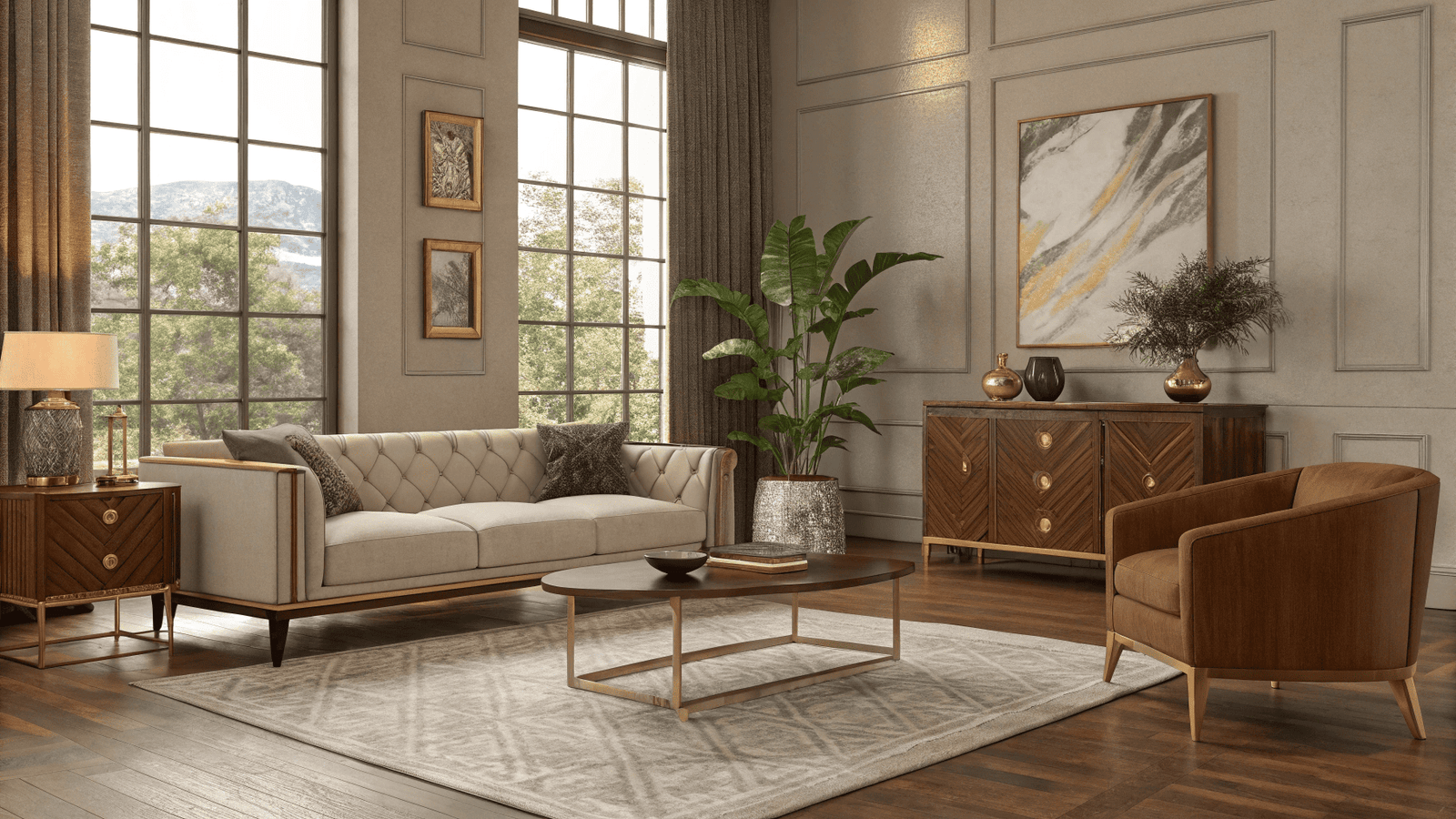

Struggling to turn a complex sculpture design[^1] into reality? The process has many hidden risks. We manage every detail to make sure your vision is built to last.

The best techniques involve a systematic approach[^2]. This starts with smart structural design[^3] and precise material selection[^4]. It continues with expert welding[^5] and careful finishing[^6] to guarantee both safety and beauty. This ensures the final piece is stable and visually stunning.

It seems simple on the surface, but the real work is in the details. Getting it right means controlling every step, from the unseen internal frame[^7] to the final polish[^8]ed surface. Let’s break down what that really means for your project and explore the techniques that separate an average sculpture from an exceptional one.

How do you design a sculpture's structure for safety and looks?

Worried your large sculpture might not be stable or look right? Poor internal design can ruin a project. We build a strong, hidden foundation for every single piece.

A great sculpture starts with a solid plan. We create an internal steel frame that supports the entire structure safely. This frame is engineered to handle weight, wind, and weather, all while staying completely invisible from the outside, protecting the artist’s original vision.

The success of a large-scale sculpture depends entirely on what you can’t see. I’ve seen projects fail because the focus was only on the outer shell, ignoring the forces of nature. The internal structure is the true hero of the piece. We approach this with a two-part strategy: building a strong skeleton and then perfectly cladding it with a metal “skin.”

The Internal Frame: The Unseen Hero

The internal frame[^7], or armature, does all the heavy lifting. We use structural steel[^9] or stainless steel to build this skeleton. Our engineers run calculations to make sure it can withstand wind loads, its own weight, and any other environmental stress[^10]. This is not just about making it stand up; it’s about making it last for decades. Every connection point is designed for maximum strength, so the sculpture remains safe and stable over its entire lifespan.

Sectioning the Outer Skin: The Perfect Fit

Once the frame is designed, we plan how to cover it with the stainless steel “skin.” A complex, curved sculpture can’t be made from one piece of metal. We use software to divide the outer surface into manageable panels. The layout of these panels is critical. We plan the seam lines[^11] to flow with the sculpture’s form, making them almost invisible after welding and polishing. This careful planning ensures a smooth, continuous surface that looks like a single, solid form.

What's the right way to cut, shape, and weld stainless steel?

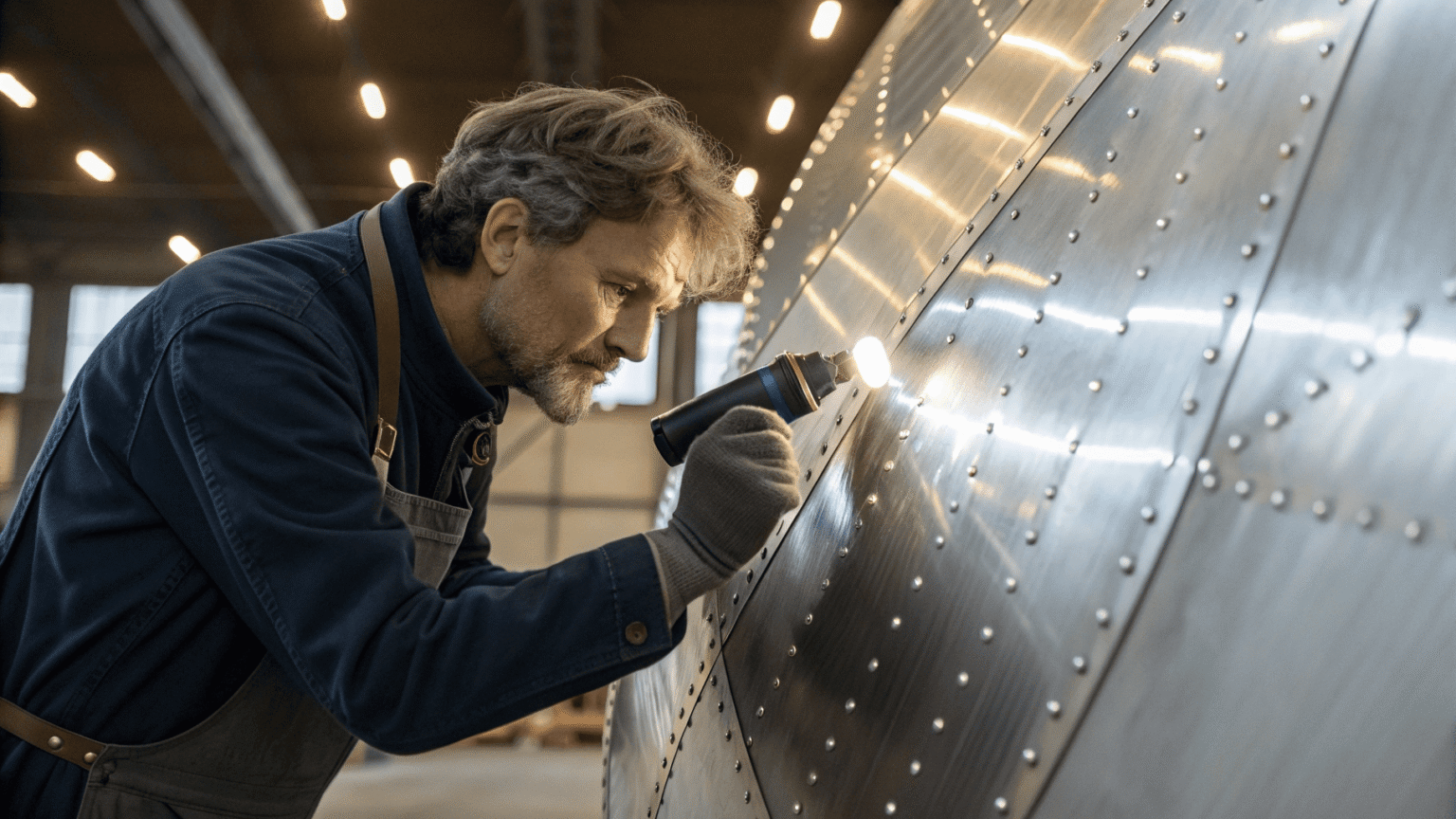

Have you seen stainless steel warp or crack after welding? The wrong technique causes permanent damage. We match our methods to the material for flawless results every time.

The right technique depends on the steel’s thickness and grade. We use methods like laser cutting[^12] for precision and careful forming to avoid stress. Welding is done in a specific sequence to prevent distortion, making sure each seam is strong and clean.

This stage is where raw material starts to become art. It requires a deep understanding of how metal behaves. A few years ago, a client brought us a piece from another fabricator that was badly warped. The surface looked wavy because they used the wrong welding sequence[^13] on thin panels. It was a costly mistake that we avoid by treating fabrication as a science.

Choosing the Right Material and Cut

First, we select the right grade of stainless steel. For outdoor sculptures, we almost always use grade 316 for its superior corrosion resistance. For indoor pieces, 304 is often sufficient. Then, we cut the panels. For intricate shapes, we use high-precision laser cutting[^12]. This gives us clean edges and exact dimensions, which is crucial for a perfect fit-up later.

Forming and Welding with Care

Next, we shape the flat panels into the curved forms[^14] needed for the sculpture. This is done using rollers and presses. We do this slowly to avoid work-hardening the metal or creating stress points. When it’s time to weld, we tack the panels onto the internal frame[^7]. We use a specific welding sequence[^13], often alternating sides of the sculpture, to distribute heat evenly. This simple step is the key to preventing the metal from warping. It’s a slow process, but it’s the only way to get a perfect result.

Why is finishing so critical for a sculpture's final appearance?

Is your finished sculpture looking dull or uneven? A poor polish can ruin the entire effect. Our finishing process creates the exact texture and shine you imagined.

Finishing is more than just cleaning up. It defines the sculpture’s texture and how it interacts with light. Whether it’s a perfect mirror polish[^15] or a uniform brushed finish[^16], this final stage requires immense skill and patience to achieve a flawless, high-end look.

I always tell my team that the last 10% of the work determines 90% of the impression. Finishing is where the true artistry comes in. It’s a physically demanding, multi-step process that can’t be rushed. The difference between a good finish and a great one is measured in hours of meticulous labor. I remember one project, a large, flowing ribbon shape, where our top craftsman spent two full weeks just on the final polish[^8] to make sure every reflection was distortion-free.

From Rough Welds to a Seamless Surface

The first step is grinding down the welds. The goal is to make every seam completely disappear. We start with a coarse-grit abrasive disc to remove the excess weld material, then progressively move to finer and finer grits. Each step removes the scratches from the previous one. This process is repeated until the entire surface is smooth and uniform, with no visible sign that the sculpture was ever made from separate panels.

Creating the Final Texture

Finally, we create the desired finish.

Finish Type | Process | Artisan Skill Required |

Mirror Polish | Buffing the surface with a series of polishing compounds, from coarse to super-fine, until it becomes reflective like a mirror. | Extremely High. Requires a keen eye to spot tiny imperfections and the patience to remove them. |

Brushed Finish | Creating a uniform pattern of fine lines using an abrasive belt or pad. The direction and pressure must be perfectly consistent. | High. Requires a very steady hand to avoid an uneven or “wavy” appearance. |

Satin Finish | A soft, low-gloss look that sits between brushed and mirror. It’s achieved with special abrasives that create a smooth, non-reflective surface. | High. It is difficult to achieve perfect uniformity over a large, curved surface. |

How can you guarantee quality in large, complex sculptures?

Are you afraid of surprises when your large-scale sculpture is delivered? A lack of process control leads to costly mistakes. Our system ensures quality is built-in from start to finish.

**We guarantee quality through a unified system. It combines standardized engineering, detailed craftsmanship[^17], and strict quality checks at every single stage. This integrated approach prevents errors, ensures stability, and delivers a final product that perfectly matches the design.**

For big, complicated pieces, you can’t just hope for the best. You need a rock-solid system. Relying on one “master craftsman” is a risk. What if they get sick? Instead, we rely on a process that everyone on the team follows. This process is built on clear drawings, constant checks, and taking responsibility for every step. It’s how we turn an ambitious design vision into a dependable, on-time reality without any last-minute drama.

Start with a Digital Blueprint

Everything begins with detailed 3D models and shop drawings. Before we cut a single piece of metal, we build the entire sculpture digitally. This allows us to identify and solve potential problems on the computer, not on the factory floor where mistakes are expensive. Everyone, from the project manager to the welder, works from the exact same set of plans. This eliminates guesswork and ensures every part fits together as intended.

In-Process Quality Checks

We don’t wait until the end to check our work. Quality control is an ongoing activity.

Stage | Key Checkpoint | Purpose |

Design | Structural Analysis & Material Specs | Ensure safety, stability, and longevity. |

Fabrication | Panel Fit-Up & Alignment on Frame | Guarantee seamless joints and accurate form. |

Welding | Weld Penetration & Consistency | Confirm full structural integrity of every seam. |

Finishing | Surface Uniformity & Texture Check | Achieve the exact aesthetic and light reflection. |

This continuous loop of checking and re-checking means we catch any small deviation early. It’s a disciplined approach that ensures the final piece is not only beautiful but also built with absolute precision and integrity.

Conclusion

Creating a great stainless steel sculpture is about total process control. From a strong internal design to a perfect final polish[^8], every step matters for a beautiful, lasting result.

[^1]: Explore expert insights on turning intricate sculpture designs into stunning realities.

[^2]: Learn how a systematic approach can enhance the quality and durability of sculptures.

[^3]: Discover the importance of structural design in ensuring the longevity of sculptures.

[^4]: Understand how the right material selection can affect the sculpture’s performance and aesthetics.

[^5]: Find out how expert welding techniques contribute to the strength and beauty of sculptures.

[^6]: Explore how careful finishing can elevate the visual appeal of a sculpture.

[^7]: Learn about the critical role of the internal frame in supporting large sculptures.

[^8]: Learn how the final polish can dramatically enhance the overall look of a sculpture.

[^9]: Discover why structural steel is a preferred choice for creating durable sculptures.

[^10]: Learn about the impact of environmental stress on the design and durability of sculptures.

[^11]: Explore how seam lines can affect the visual continuity of a sculpture.

[^12]: Explore how laser cutting enhances precision and quality in sculpture creation.

[^13]: Understand the significance of welding sequence in preventing distortion during fabrication.

[^14]: Learn about the techniques used to shape metal into beautiful curved forms.

[^15]: Discover the meticulous steps required to achieve a flawless mirror finish.

[^16]: Explore the techniques behind creating a uniform brushed finish on sculptures.

[^17]: Discover how skilled craftsmanship elevates the quality and beauty of sculptures.