Crafted for Luxury: NEXTOP’s Complete Furniture Collection for LVMS Café Seoul

Project Snapshot

Project name: LVMS Café — Louis Vuitton Maison Seoul

Location: Seoul, Korea

Client / Owner: Louis Vuitton Maison Seoul (LVMS)

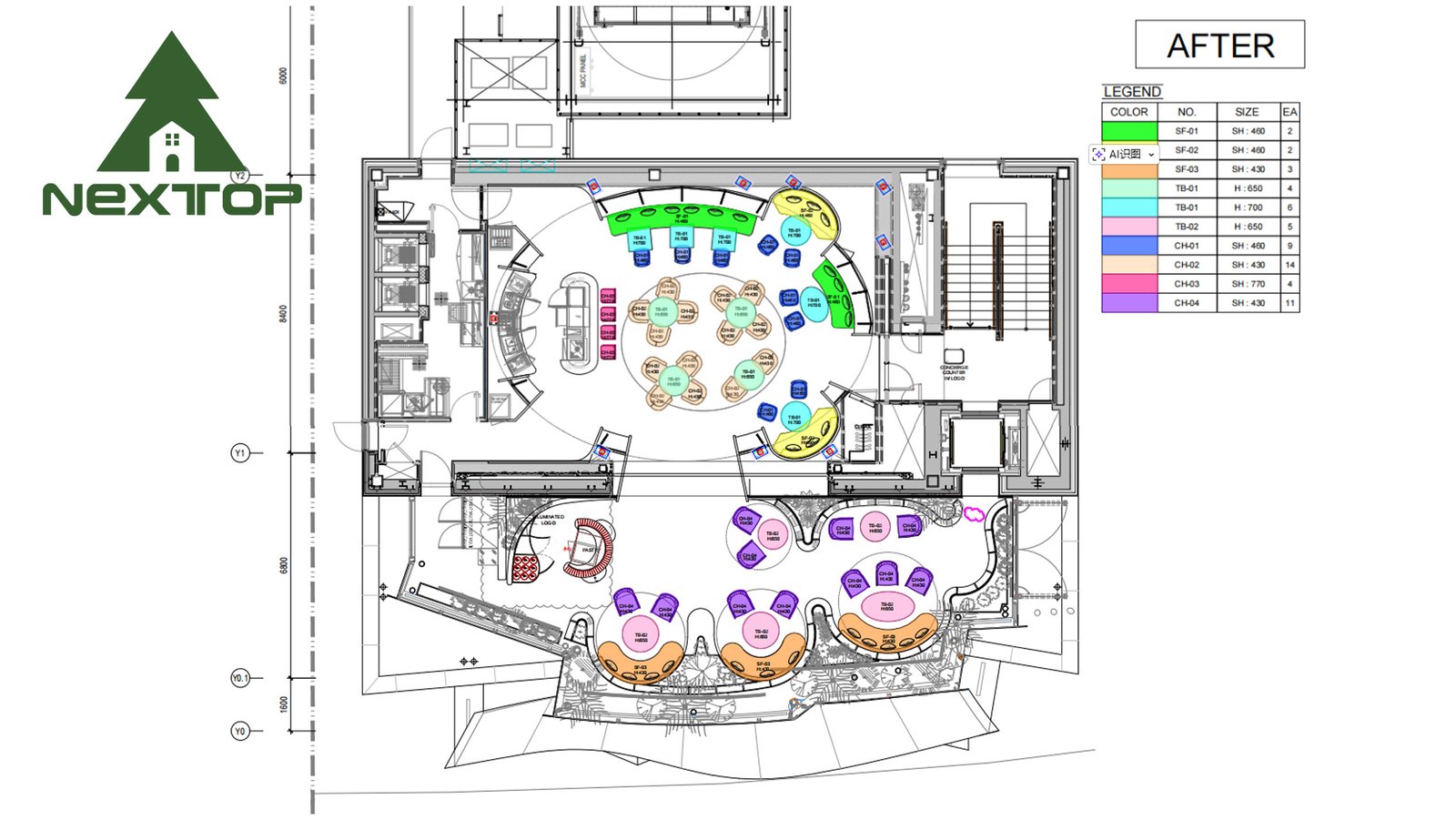

Scope delivered by NEXTOP: Manufacture and supply of all café furniture items including: pastry counter (marble top with dark wood veneer cabinetry + necessary metal structure), café tables (metal tops), sofas, lounge chairs, dining chairs and related loose furniture.

Project Background & Intent

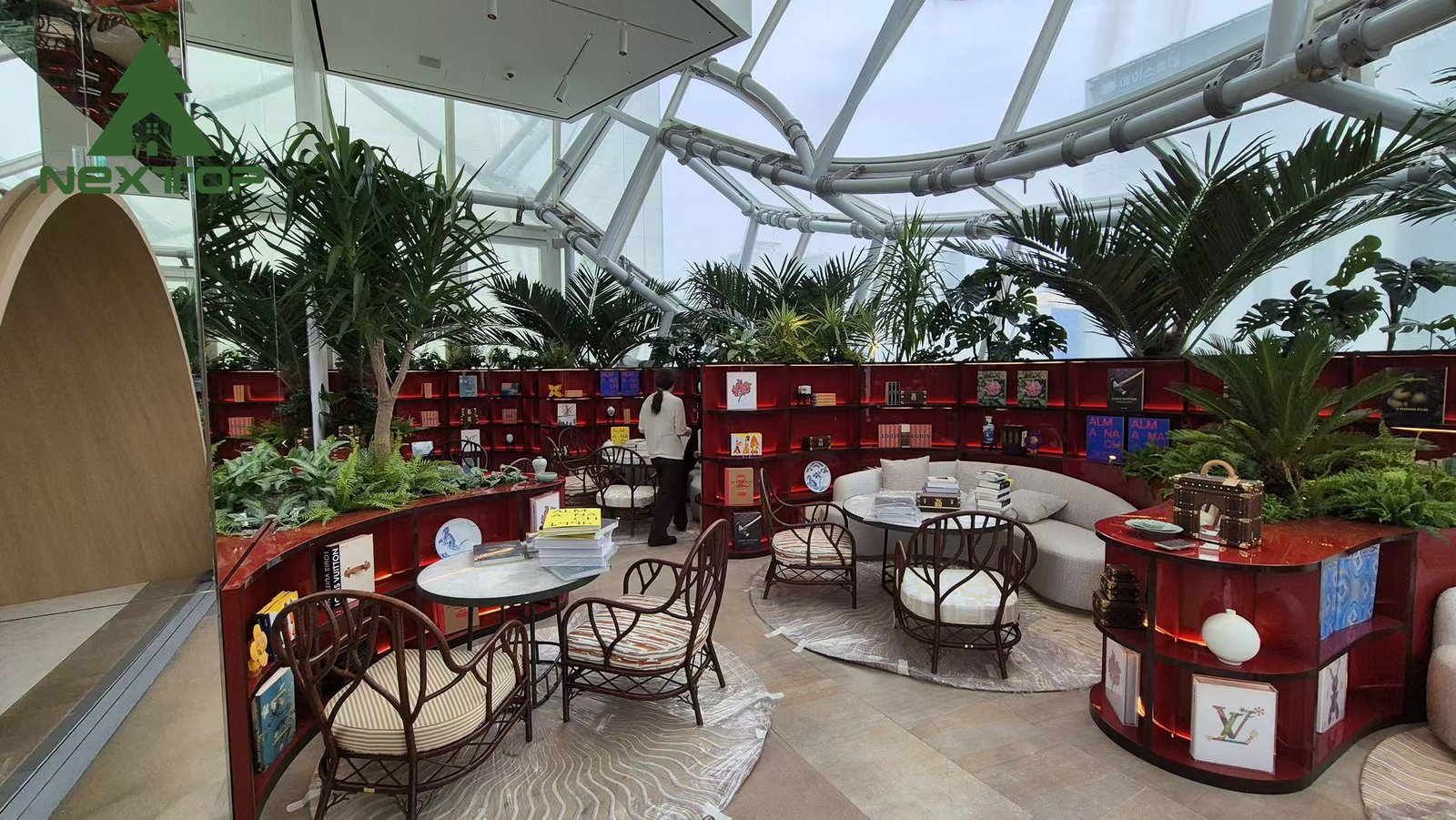

Located within the Louis Vuitton Maison Seoul flagship, LVMS Café is conceived as an immersive extension of the Louis Vuitton lifestyle — a refined setting where French savoir-faire intersects with local Korean flavors. The space requires furniture that communicates restraint and luxury through materiality and craftsmanship rather than overt ornament. NEXTOP was engaged as the manufacturing partner to realize the client’s design documentation into physical furniture that meets both the aesthetic brief and the operational demands of a high-end commercial café.

Our remit was strictly manufacturing and supply: to produce high-quality, brand-appropriate furniture pieces exactly to the supplied shop drawings, technical specifications, and approved material samples.

Delivered Items & Technical Summary

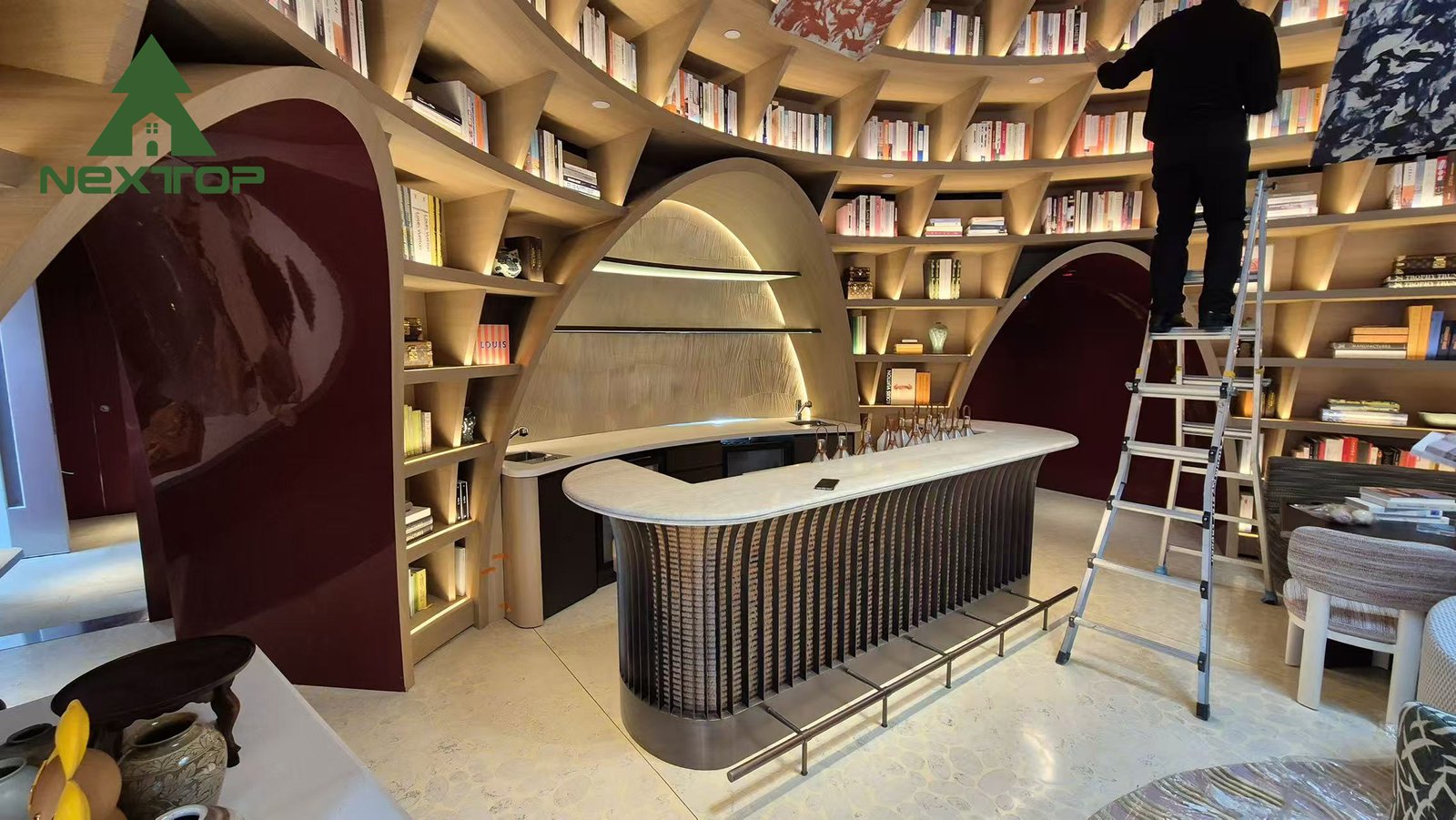

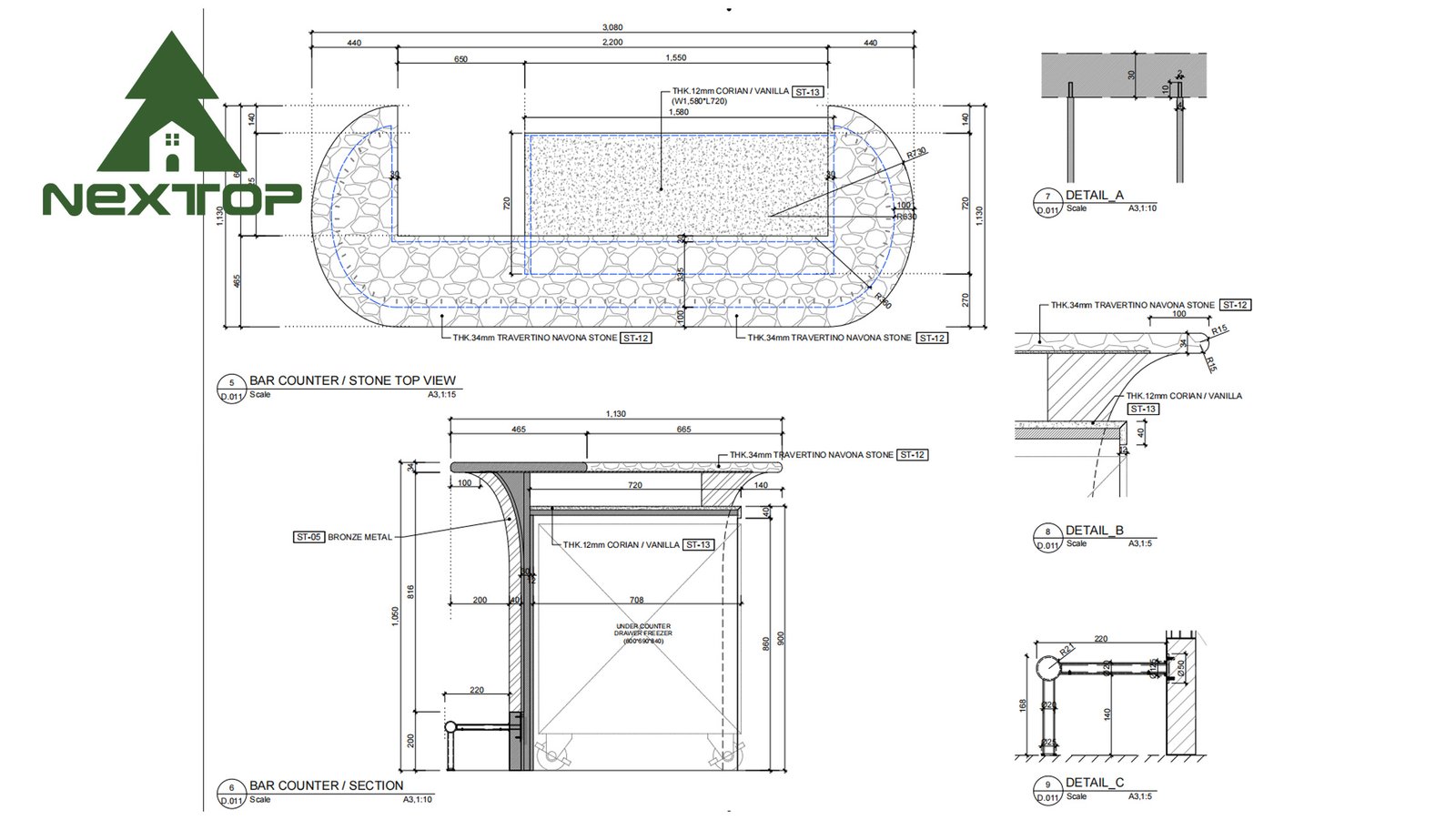

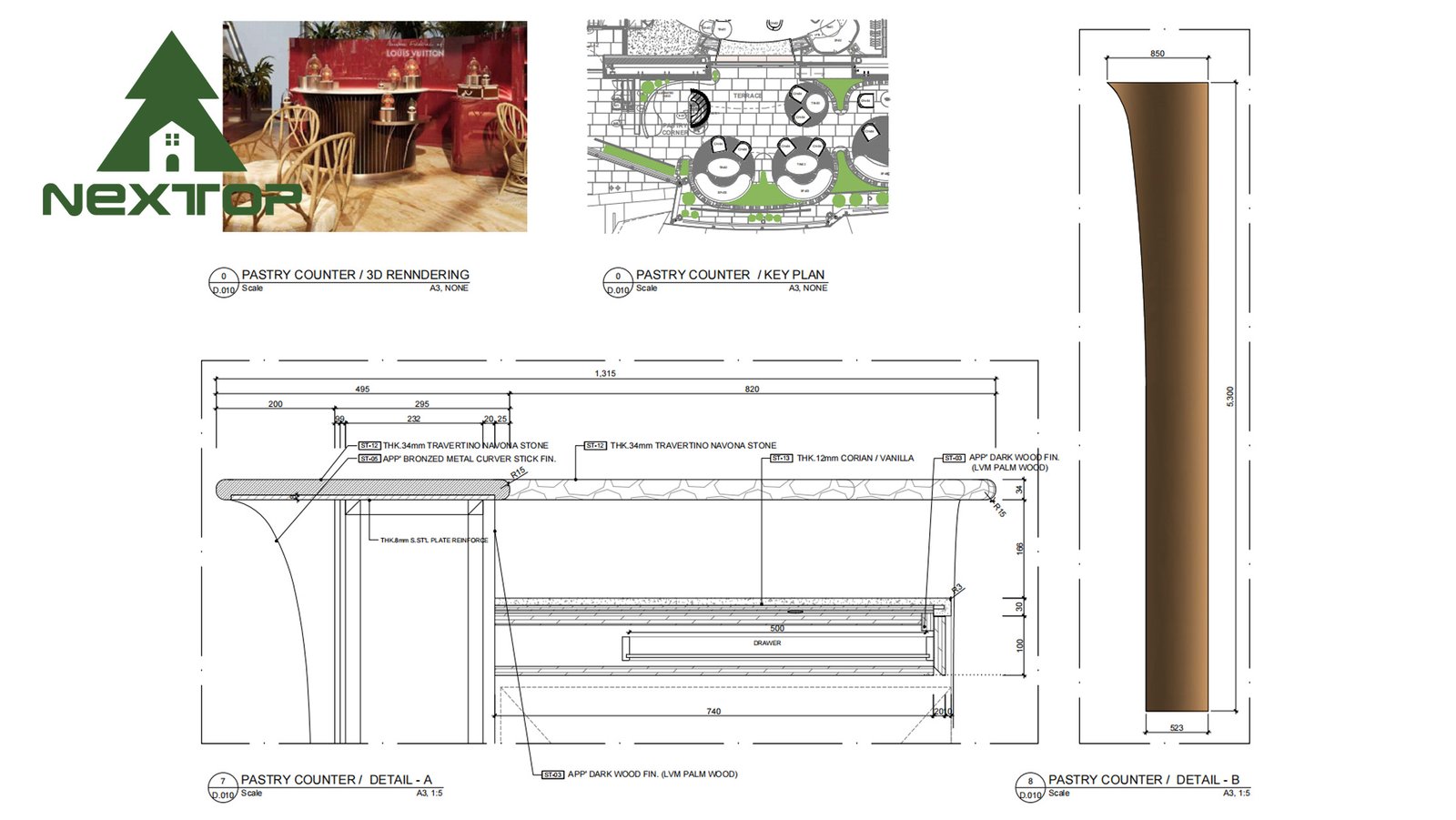

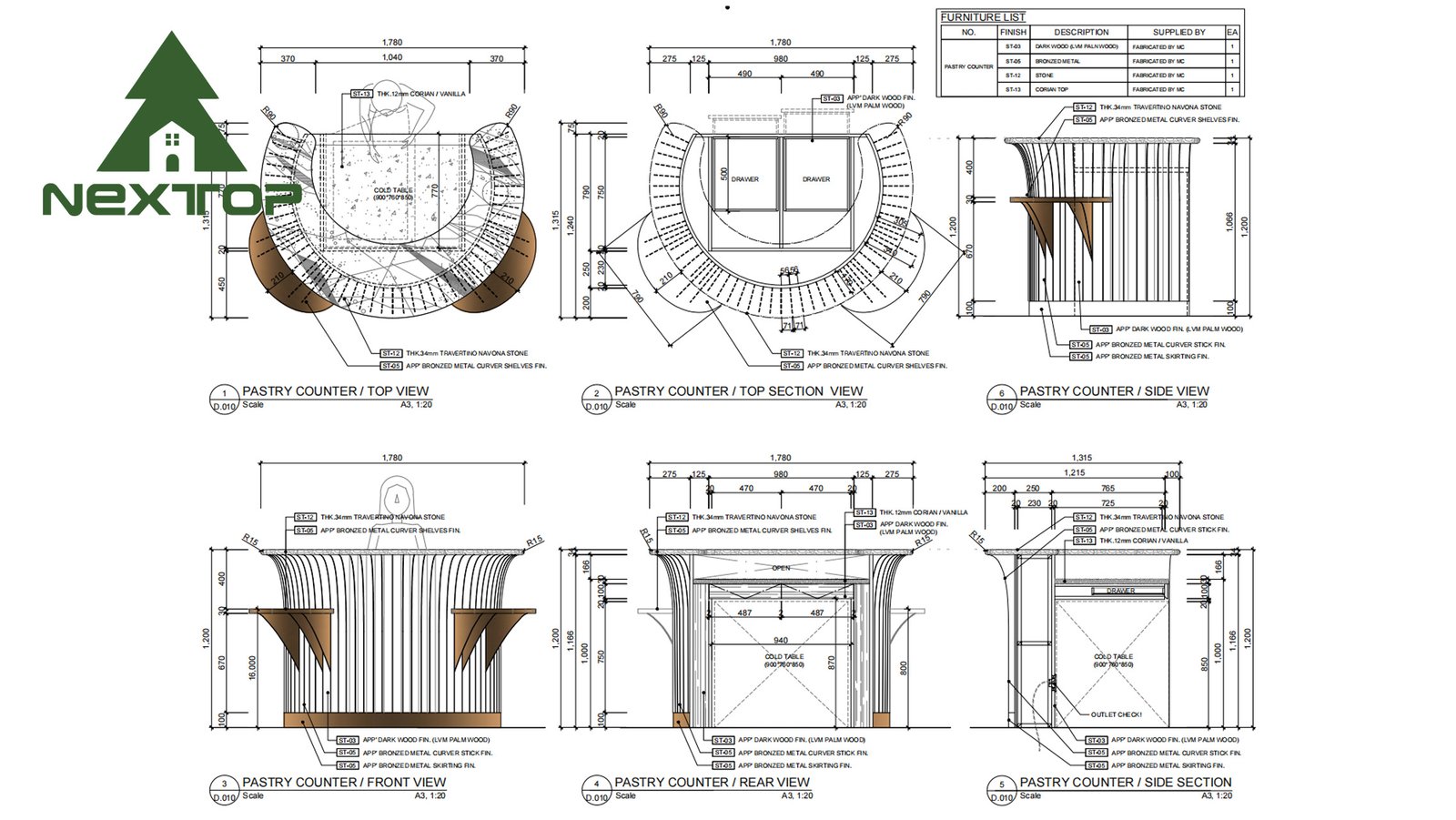

1. Pastry Display Counter (Manufactured Supply)

- Top material:High-grade natural marble slab — selected vein and finish per client sample. Polished finishing with sealed joints for hygiene and ease of cleaning.

- Cabinetry:Deep-tone wood veneer (dark wood finish) over engineered core for dimensional stability. Grain orientation and matching performed across visible panels to ensure consistent, premium appearance.

- Structural elements:Concealed metal subframe and reinforcement where required for structural integrity (frames and mounting points only — no additional metal decorations). Metal used is stainless steel for corrosion resistance and long life; connections TIG/MIG welded and ground smooth.

- Functional layout:Internal shelving and service access as per client layouts; ventilation and service cutouts provided to match equipment interfaces (client-specified).

- Finish & protection:Stone sealed with commercial food-grade sealer; wooden surfaces finished with low-sheen protective lacquer to resist scuffs and spills while preserving natural texture.

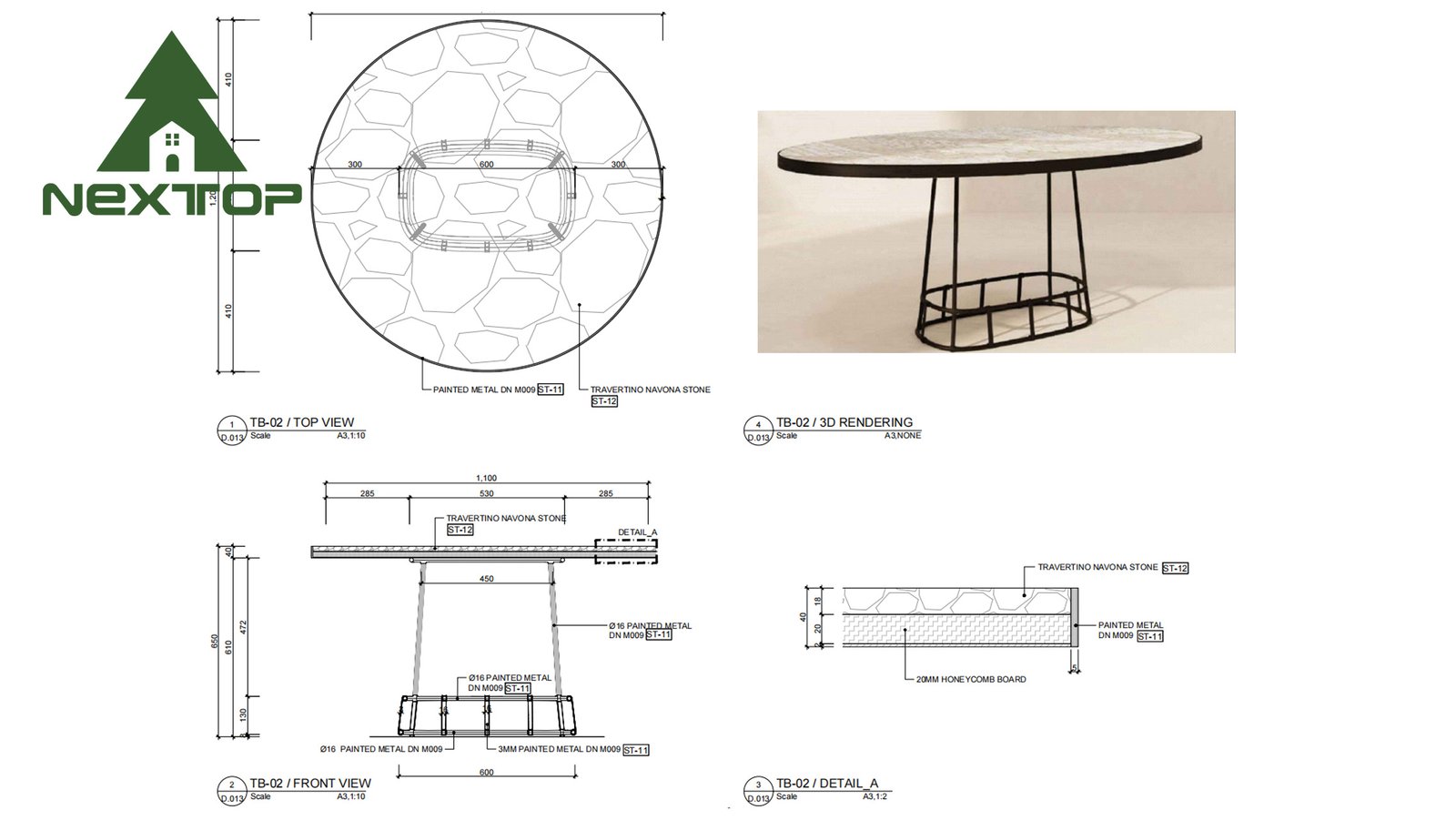

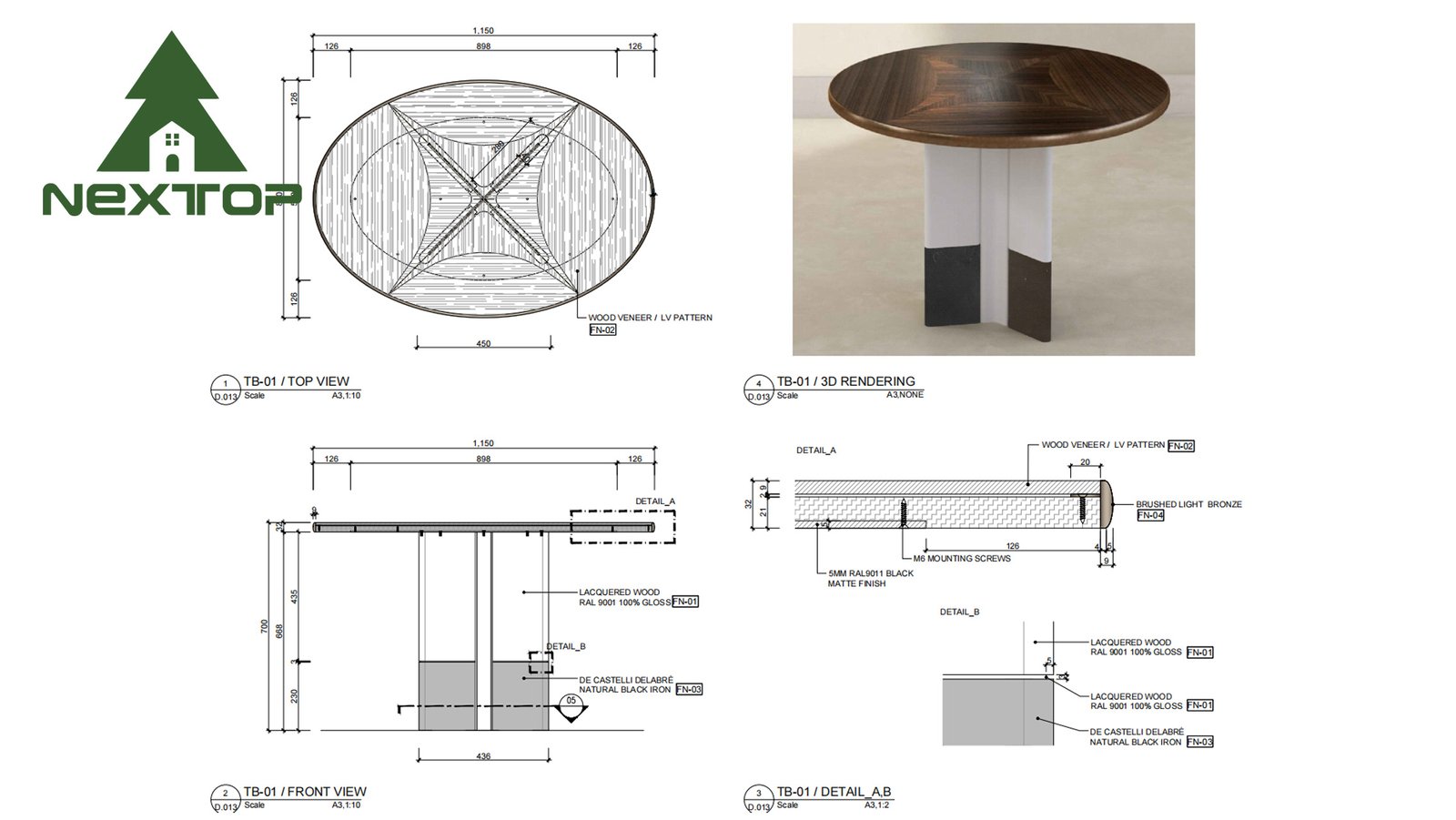

2. Café Tables

- Tabletops:Metal plate tops (client-specified metal alloy/grade) with precision flatness tolerances. Surface treatments performed per sample: fine mechanical preparation and specialist finish (brushed / micro-textured / powder coat as specified).

- Legs & supports:Metal bases fabricated to shop drawings; welded and machined for tight tolerances to ensure stability on commercial flooring. Fixing interfaces provided for on-site attachment (bolts, leveling feet as required).

- Durability:Tops treated for abrasion and stain resistance; edges profiled to avoid sharpness and to improve user comfort.

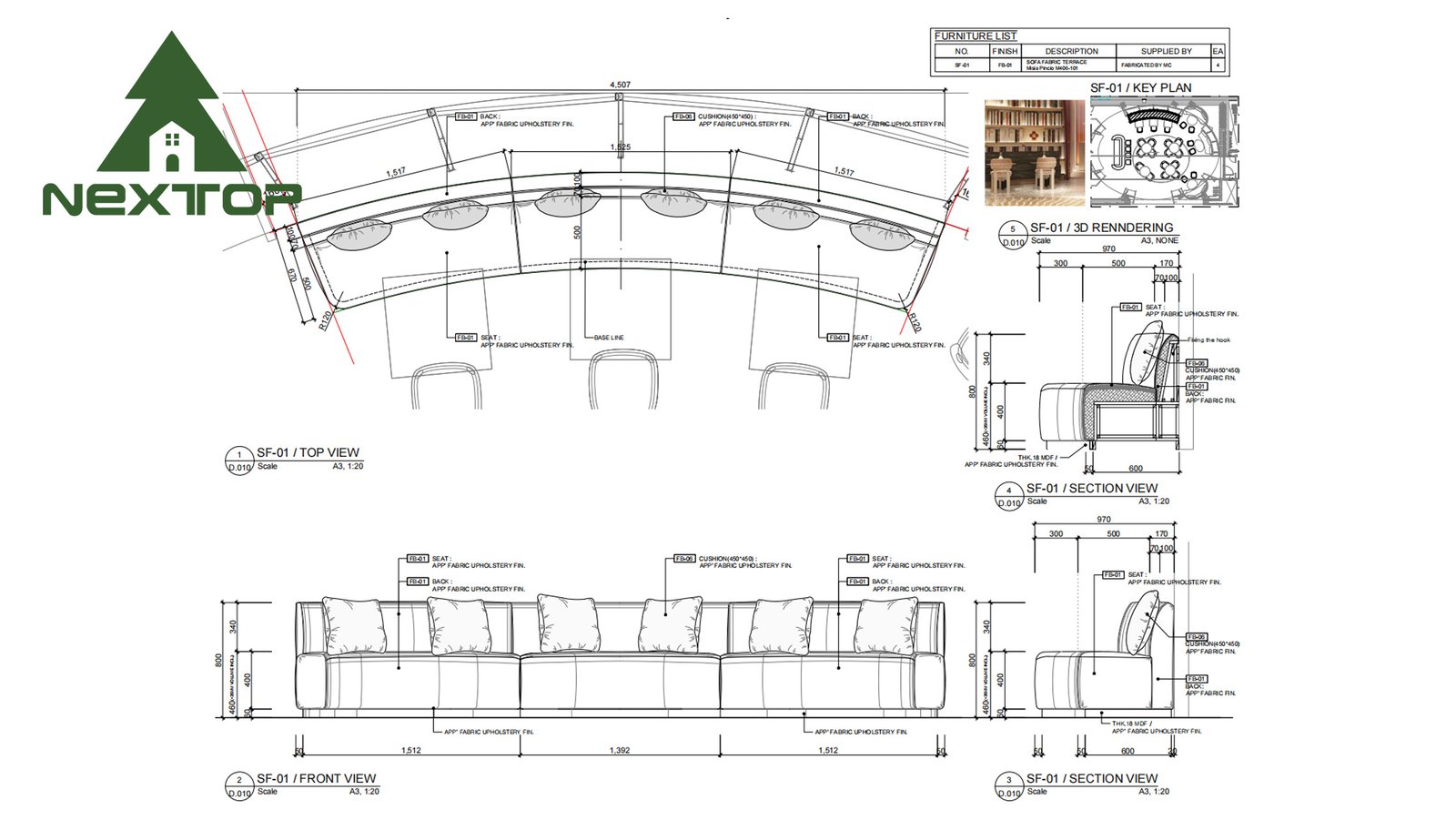

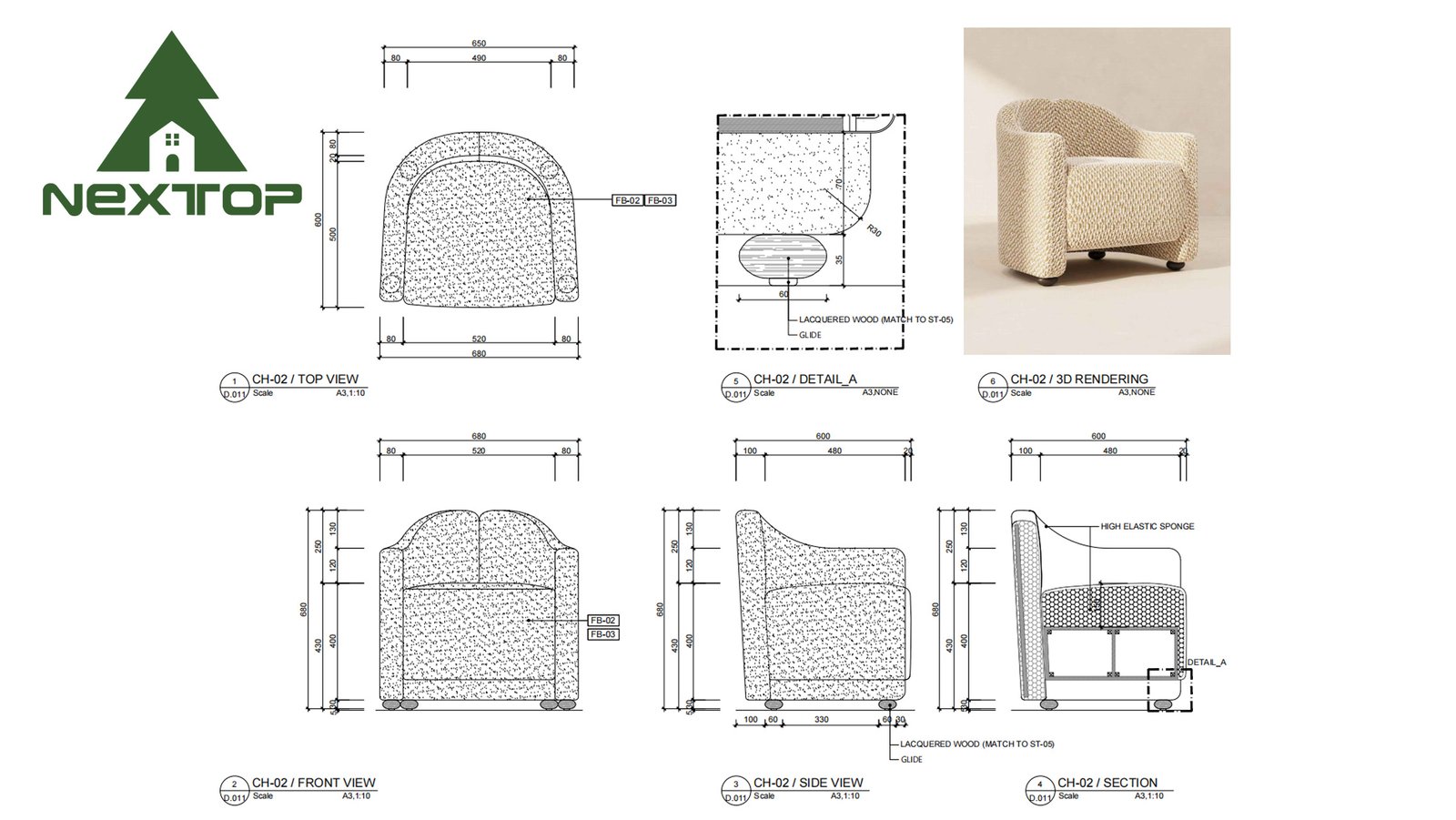

3. Seating — Sofas, Lounge Chairs, Dining Chairs

- Construction:Robust hardwood or engineered frames (as specified) with commercial-grade joinery and reinforced stress points for heavy use. All frames checked to pass EN / BIFMA style commercial strength criteria where applicable.

- Cushioning & upholstery:High-density foam with specified resilience (comfort and sag resistance), wrapped and upholstered using client-approved leather or textile. Stitching, piping, and seam placement executed to luxury standards.

- Legs & small fittings:Metal or timber legs as per drawings; finishes matched to sample references. Removable cushion covers provided where requested for maintenance.

- Ergonomics:Seat heights, back angles and seat depths manufactured to the dimensions on the client drawings to deliver the intended comfort profile.

Manufacturing Quality Assurance & Process

Although NEXTOP did not provide design or installation, our production workflow ensured every item met the client’s technical and brand expectations:

- Document Verification:Production teams signed off the client’s design drawings, part lists, and material schedules prior to tooling. Any ambiguities were flagged and clarified through the client’s design team (client responsibility to resolve).

- Material Sampling & Approval:We produced and delivered material samples and mock-ups (stone, veneer, upholstery swatches, metal finish samples) for client approval before full production.

- Prototype / Sample Units:Key items (a pastry counter module and representative seating unit) were manufactured as pre-production samples and approved before batch manufacturing.

- Controlled Production:CNC machining, precision metalwork and woodworking carried out in climate-controlled production lines to minimize dimensional variance. Skilled craftsmen handled upholstery and finishing.

- Multi-stage QC:Dimensional inspection, finish inspection, structural load testing (where applicable), and upholstery seam inspection carried out at defined checkpoints. Non-conforming items were reworked or remade.

- Packing & Export Preparation:Each unit was protected with high-density foam, timber-crated where needed, and labeled with handling instructions for fragile surfaces (marble) and orientation. Export documentation prepared to client instructions.

Scope Limits & Responsibilities

- Design:All design drawings, engineering details and shop drawings were provided by the client or their design consultant. NEXTOP manufactured strictly to these documents.

- Installation & On-site Work:Installation, site adjustments, interface with MEP and final fit-out were excluded from NEXTOP’s scope. On-site supervision by NEXTOP could be provided under a separate agreement if requested.

- Additional Metalwork / Decorations:The project scope did not include additional bespoke metal decorative elements beyond the necessary structural metalwork inside cabinetry and table supports. Any separate metal decorative scope would require a contract variation.

Project Highlights & Value Delivered

- Premium material execution:Marble pastry counter tops and deep wood veneer cabinetry executed to luxury finish expectations, providing a restrained but unmistakably premium focal point.

- Commercial durability:Furniture engineered for high-turnover café operation — materials, finishes and structural choices minimized maintenance while preserving elegance.

- Precision manufacturing:Samples and pre-production units ensured visual and dimensional conformity to the client’s design intent.

- Clear delivery boundary:By focusing on manufacture and supply only, NEXTOP delivered efficient production throughput and quality control while leaving installation coordination to the client’s on-site teams.

Handover Deliverables

- Packaged furniture units delivered to the nominated delivery point (per client shipping instructions).

- As-built packing lists and itemized crate contents.

- Material certificates (stone grade, metal grade, upholstery origin) where provided by suppliers.

- Care & maintenance guidelines for marble, wood veneer, metal finishes and upholstery.

- Inspection checklists and factory quality records for each lot.

Conclusion

As the doors of LVMS Café Seoul open each day, the space comes alive with the warmth of crafted materials, the quiet confidence of well-engineered structures, and the refined harmony of Korean artistry and global luxury. Every table that welcomes a guest, every sofa that invites a moment of pause, and every counter that supports the café’s rhythm began as a concept, shaped into reality through our craftsmanship.

For NEXTOP, this project is more than furniture production—it is the creation of a setting where experiences unfold, conversations begin, and the essence of the brand is felt in every detail. And this is the standard we bring to every project we touch.

Start Your Project

Ready to Bring Your Vision to Life?

Let’s create furniture that elevates your space with precision, beauty, and long-term performance.

Browse Nextop Solutions Full Products

Metal Cladding & Architectural Features

Partitions.Walls. Columns. Ceilings.Sculptures. NEXTOP fabricates stunning architectural metal elements from brushed brass to mirror stainless steel, fully tailored to your shop drawings.

Custom Furniture Production

Built-in cabinets, counters, wardrobes, and bespoke furniture — all manufactured with precision joinery and luxury finishes.

One-Stop Fit-Out Supply

We handle sampling, prototyping, fabrication, packing, and coordination — ready for smooth handover to your installer team on-site.

High-Spec Finishing

RAL powder coating, antique brass patina, PVD coating, vibration patterns — all in-house with strict QC.

Enquiry Form

Contact our Customer Services team by completing the form. We will endeavour to respond within 24 hours.