Introduction

Worried your custom furniture[^1] won’t match the design or last long? This common fear can ruin a project’s budget and timeline. True quality comes from a professional system[^2].

High-quality custom furniture[^1] is made through a controllable, repeatable professional system[^2]. This process includes engineering-level design[^3], precision manufacturing[^4] with CNC machines[^5] and skilled artisans[^6], strict material selection[^7], multi-stage quality control[^8], and a final trial assembly[^9] before expert packaging and delivery. It’s a verifiable, end-to-end process.

It’s easy to think that “custom” just means “made to order.” But that doesn’t guarantee quality. The real secret is in the process behind it. A beautiful design is just the start. Turning that vision into a durable, functional, and perfectly finished piece of furniture requires a system you can trust. Let me walk you through how we make that happen. It is a journey that starts long before the first piece of wood is ever cut.

How do we turn a design concept into a buildable plan?

A beautiful drawing does not guarantee a functional piece of furniture. Misinterpretations can lead to costly mistakes and delays, creating a product that simply doesn’t work as intended.

We translate your design into a detailed, buildable plan through engineering-level shop drawings. Our engineers analyze the concept, define all materials, specify dimensions, and confirm the construction methods. This blueprint ensures the final piece is both beautiful and structurally sound.

The first step is always the most important. We take your initial designs, whether they are simple sketches or detailed renders, and begin the engineering process. This isn’t just about copying what we see. It’s about translating an artistic vision into a technical blueprint that our manufacturing team can execute flawlessly. I remember a project for a boutique hotel lobby. The designer had a stunning concept for a curved reception desk. It looked great on paper, but we had to figure out how to make it stable and practical for daily use.

From Vision to Blueprint

Our engineers create comprehensive shop drawings. These are not just basic outlines. They are highly detailed documents that specify every single component. This includes the exact type of wood, the thickness of the metal, the joinery techniques[^11], and the placement of every screw and hinge. We often create 3D models[^12] to visualize the piece from all angles, ensuring there are no surprises.

Material and Structure Verification

During this stage, we also verify that the specified materials and structure will work. Will the chosen wood warp in the project’s climate? Is the metal frame strong enough to support the marble top? We answer these questions before production starts.

Aspect | Design Concept | Engineering Shop Drawing |

Details | General shape, color, style | Precise dimensions, joinery, materials |

Structure | Artistic representation | Load-bearing analysis, hardware specs |

Goal | Communicate the vision | Provide a buildable instruction manual |

How do we maintain consistency in manufacturing?

You ordered one hundred identical tables, but they all look slightly different. Inconsistencies undermine the professionalism of a project and create headaches during installation. We prevent this from happening.

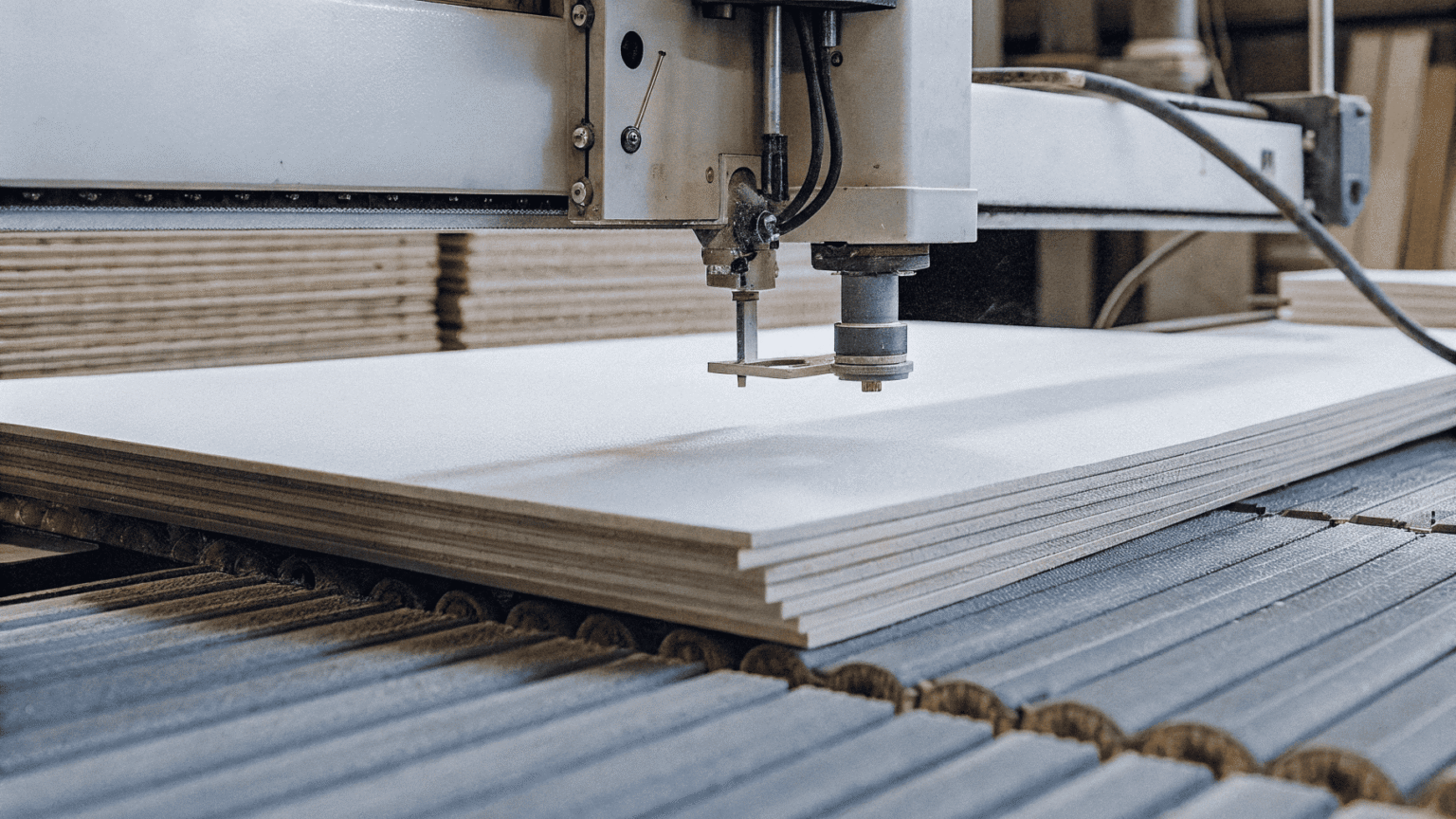

We maintain consistency by combining modern technology with traditional skill. CNC machines[^5] perform precise, repeatable cuts with digital accuracy. Then, our experienced craftsmen handle the assembly, finishing, and details that require a human touch, ensuring every item meets the same high standard.

Once the shop drawings are approved, we move to the factory floor. This is where we balance technology and human skill. You can’t have one without the other if you want consistent, high-quality results, especially for a large order. For a recent hotel project, we had to produce 250 identical nightstands, each with intricate paneling. Using machines for the cuts and artisans for the assembly was the only way to guarantee every single one was a perfect match.

The Role of CNC Machining

CNC (Computer Numerical Control) machines are the foundation of our consistency. We input the exact dimensions from our shop drawings, and the machine cuts the components with incredible precision, down to a fraction of a millimeter. This means that the first piece and the five-hundredth piece are identical. This is impossible to achieve by hand. It removes human error from the most critical cutting and shaping tasks.

The Importance of Skilled Craftsmanship

However, a machine can’t assemble a complex joint, sand a curved edge to a perfect smoothness, or apply a flawless finish. That’s where our craftsmen come in. They take the precisely cut components and bring them to life. Their experience allows them to understand how materials fit together and how to achieve a finish that is both beautiful and durable.

Task | Handled by CNC Machine | Handled by Skilled Craftsman |

Cutting | Precise, repeatable cuts for all panels | N/A |

Shaping | Basic shaping, drilling, routing | Complex curves, edge profiles, sanding |

Assembly | N/A | Joinery, gluing, hardware installation |

Finishing | N/A | Staining, painting, lacquering, polishing |

How do we guarantee the furniture is durable and safe?

Your new furniture looks great, but will it withstand daily use in a busy hotel? A wobbly table or a faded finish reflects poorly on everyone and becomes a long-term liability.

We guarantee durability[^14] by selecting materials based on stability and project requirements, not just looks. Every structure and piece of hardware is tested. Our multi-stage quality control[^8] system[^15] inspects everything from raw materials to the final product before it ships.

A piece of furniture is only as good as the materials it’s made from. And even the best materials need to be put together correctly. That’s why our quality control process is not just a single check at the end. It’s a continuous system of checks that happens at every single stage of production. We don’t just hope for the best; we inspect and verify quality from start to finish. This prevents small issues from becoming big problems later on.

Selecting the Right Materials

It starts with the raw materials. We source wood, metal, stone, and fabrics based on their suitability for a commercial environment[^16]. This means we consider factors like humidity, traffic, and cleaning requirements. For example, the wood used for a project in a humid coastal area will be different from the wood used in a dry climate to prevent warping. All hardware, like drawer slides and hinges, is tested for its cycle life to ensure it can handle heavy use.

Our Quality Control Checklist

Our QC team is involved from beginning to end. They are an independent team whose only job is to find problems. They follow a strict checklist to ensure nothing is missed.

QC Stage | Key Checkpoints |

Raw Material | Moisture content, grade, finish, no defects |

In-Production | Dimensions match shop drawings, correct joinery |

Post-Finishing | Color consistency, finish smoothness, no blemishes |

Pre-Shipment | Final inspection, trial assembly, parts count |

The furniture was perfect at the factory, but it arrived damaged on-site. Shipping damage causes massive delays and unexpected costs, derailing project timelines and creating immense frustration.

We ensure a perfect arrival with two final, critical steps. First, we conduct a full trial assembly[^9] in our workshop. Second, we use professional, multi-layer packaging with clear labeling designed specifically for international transit, protecting every component until it reaches your site.

Our job isn’t done when the furniture is built. The final step—delivery—is just as important as the first. A beautiful piece of furniture is useless if it arrives broken or if it doesn’t fit together on-site. We learned this lesson the hard way many years ago. Now, our pre-shipment process is one of the most rigorous parts of our system. I once saw our team trial-assemble an entire mock-up hotel room in our workshop. It caught one small alignment issue that would have been a nightmare to fix on-site, saving the client time and money.

The Critical Step: Trial Assembly

Before anything gets packed, we assemble it. For a single large item, we build the whole thing. For a large order of identical items, we assemble several to ensure they all fit perfectly. This confirms that all parts are present, all dimensions are correct, and everything aligns as it should. We take photos and videos of the assembled pieces to send to you, so you can see the finished product before it even leaves our factory.

Packaging for Global Transit

Once trial assembly[^9] is confirmed, we carefully disassemble, label, and pack each piece. This isn’t just throwing it in a box. We use a system designed to protect against the shocks of a long journey.

Packaging Step | Description |

1. Disassembly & Labeling | Each part is clearly labeled to match an assembly guide. |

2. Protective Wrapping | Soft foam and EPE wrap protect surfaces from scratches. |

3. Corner Protection | Hard foam or plastic guards protect vulnerable corners and edges. |

4. Custom Crating | Pieces are secured inside custom-built wooden crates. |

5. Clear Reporting | We send photos of the packed goods before they are loaded. |

High-quality custom furniture[^1] is not an accident. It is the direct result of a verifiable system that covers every step from engineering design to a safe, on-time delivery.

[1]: Explore the advantages of custom furniture, including personalization and quality, to enhance your design projects.

[2]: Learn about the importance of a professional system in ensuring high-quality furniture production.

[3]: Discover how engineering-level design contributes to the durability and functionality of custom furniture.

[4]: Understand the role of precision manufacturing in creating high-quality, consistent furniture pieces.

[5]: Find out how CNC machines revolutionize furniture manufacturing with precision and efficiency.

[6]: Understand the invaluable contribution of skilled artisans in achieving high-quality finishes and details.

[7]: Discover the criteria for selecting materials that ensure durability and aesthetic appeal in furniture.

[8]: Explore how multi-stage quality control ensures that every piece of furniture meets high standards.

[9]: Learn about the trial assembly process and its importance in ensuring furniture quality before shipping.

[10]: Understand the process of turning a design concept into a practical and buildable furniture plan.

[11]: Discover various joinery techniques that enhance the strength and aesthetics of furniture.

[12]: Explore the benefits of using 3D models for visualizing and refining furniture designs.

[13]: Learn about the essential hardware specifications that contribute to the functionality of furniture.

[14]: Explore the factors that contribute to the durability of custom furniture for long-term use.

[15]: Understand how a robust quality control system prevents defects and ensures product excellence.

[16]: Explore the unique requirements for furniture designed for commercial spaces to ensure longevity.