Introduction

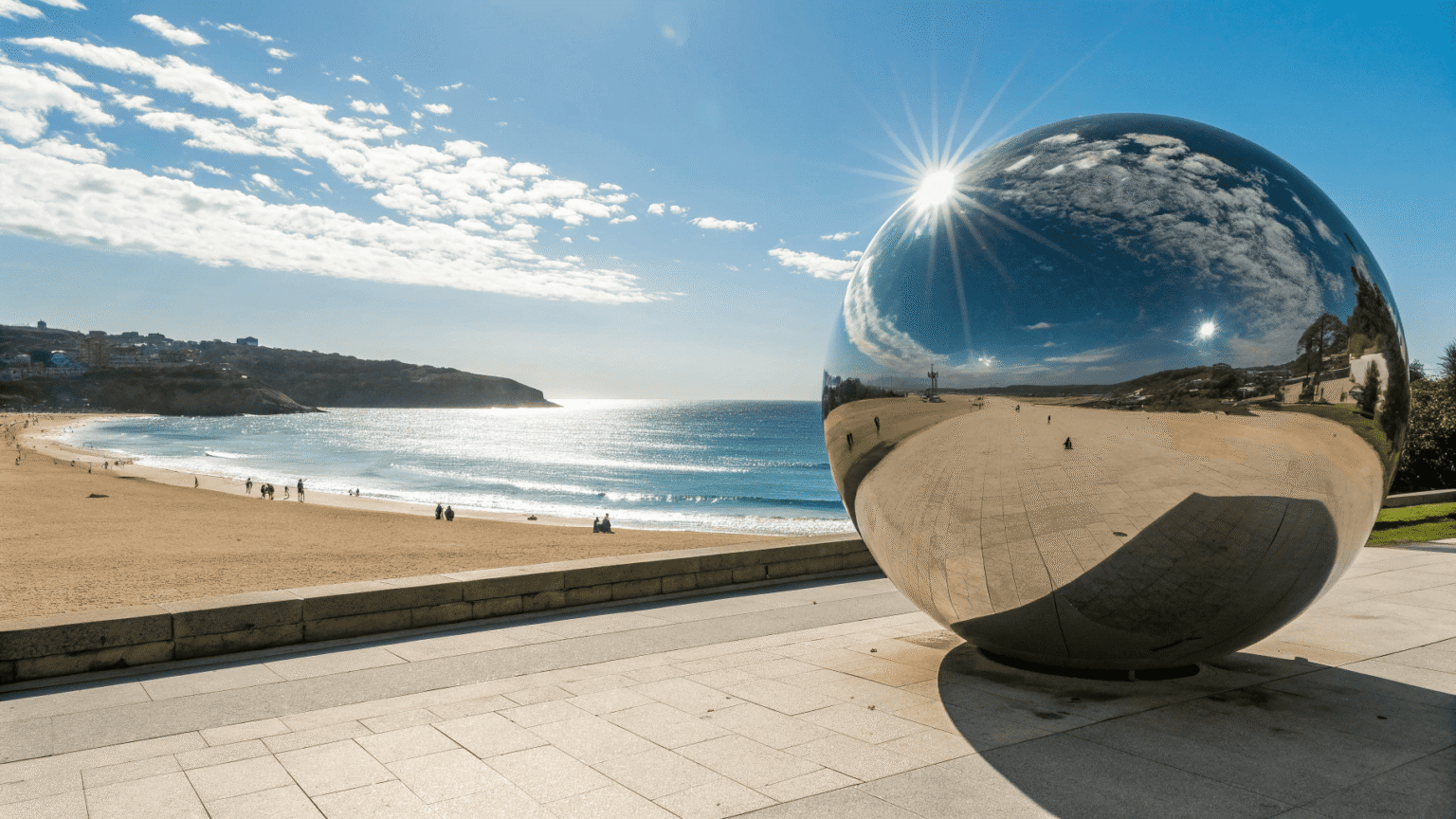

Worried your beautiful metal sculpture will rust away by the sea? The salty air and constant moisture can destroy ordinary metals. You need a solution that looks great and lasts for decades.

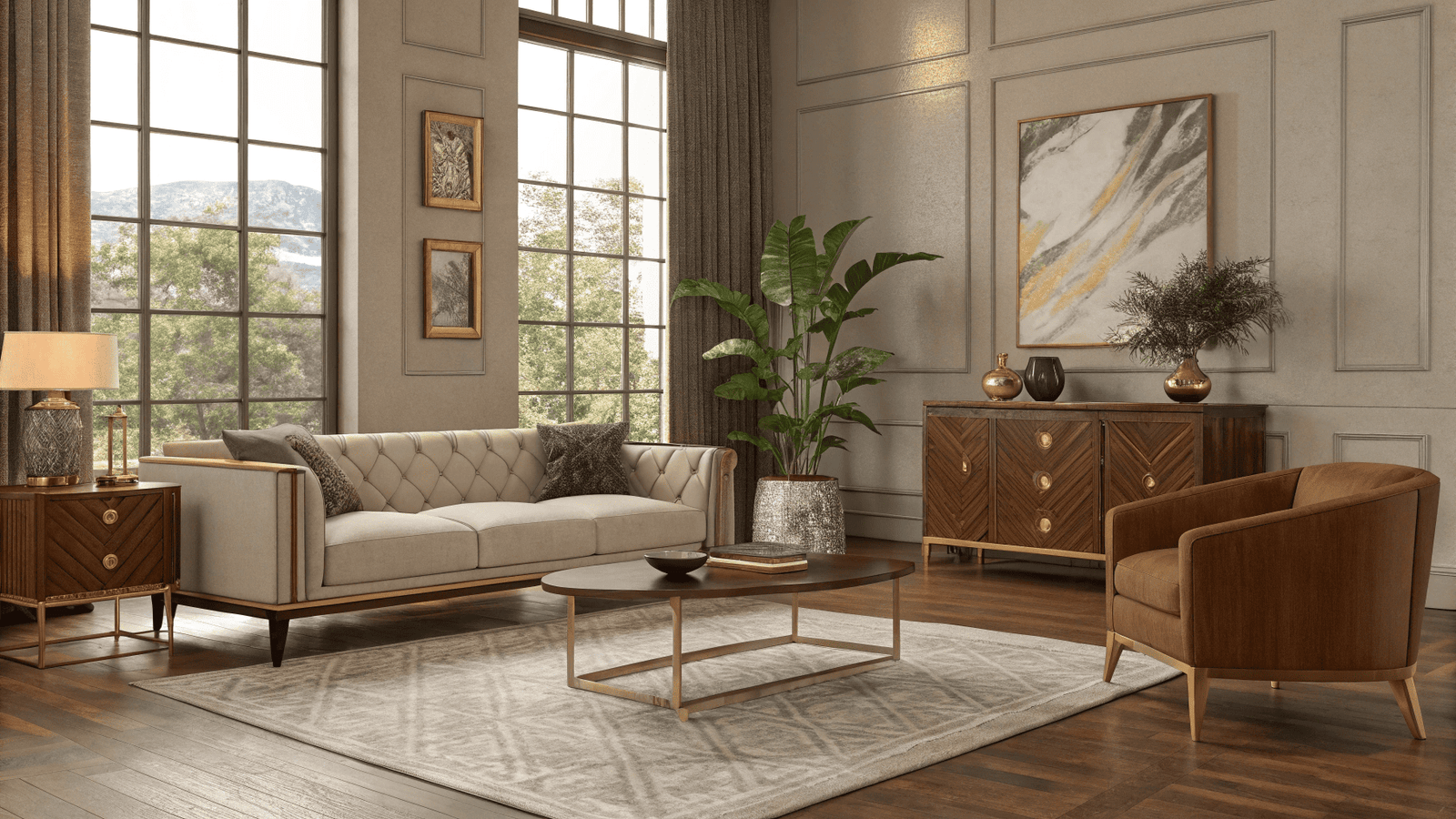

Yes, stainless steel sculptures[^1] are an excellent choice for coastal areas. Their natural resistance to corrosion, especially marine-grade alloys[^2] like 316L[^3], ensures longevity. With proper design and finishing, they can withstand salt spray[^4], high humidity[^5], and strong winds with minimal maintenance, making them a reliable investment.

I get this question all the time from architects and designers working on seaside projects. They see a stunning design on paper but worry about how it will hold up against the harsh coastal environment. They’ve seen other metals corrode and fail, and they don’t want their legacy project to become a rusty eyesore. It’s a valid concern. But I always tell them that the problem isn’t the location; it’s about choosing the right material and, more importantly, the right engineering from the start. Let’s break down why stainless steel is not just suitable, but often the best option you have.

Why is choosing the right material so critical for coastal sculptures?

Your project’s reputation is on the line. A corroded sculpture can ruin a landscape and become a safety hazard. You need a material that guarantees both beauty and structural integrity[^6] for years.

The right material is critical because coastal environments accelerate corrosion. Salt spray, constant humidity, and UV exposure attack metals relentlessly. Choosing a weak material leads to rust, structural failure[^7], and costly repairs, while a robust material like marine-grade stainless steel ensures the sculpture remains safe and beautiful.

When we talk about coastal conditions, we’re not just talking about a little bit of moisture. We are talking about a constant attack from chlorides[^8] found in salt spray[^4]. These chlorides[^8] are incredibly aggressive and can eat through standard carbon steel or even lower grades of stainless steel surprisingly quickly. I remember a project early in my career where a client insisted on a different, cheaper metal for a beachfront installation to save on the initial budget. Within two years, we were called back to assess significant rust stains and pitting. The cost to repair and replace sections ended up being far more than the initial savings. This is why we must consider the entire life cycle cost, not just the upfront material price. A sculpture is a long-term landmark. It has to withstand not only corrosion but also high winds and the occasional storm. The material’s strength and durability are just as important as its resistance to rust.

Which type of stainless steel is best for salty air?

You know stainless steel is the answer, but which kind? Choosing the wrong grade can lead to failure, just like using the wrong material. You need the specific type designed for marine use.

For salty air, 316L[^3] stainless steel is the industry standard and the best choice. It contains molybdenum, an element that significantly increases its resistance to chloride corrosion. While 304 grade is common, it will eventually rust in a coastal setting. Always specify 316L[^3] for seaside projects.

The difference between stainless steel grades is all in the chemistry, and for coastal projects, one element makes all the difference: molybdenum. Standard 304 stainless steel is great for many applications, like kitchen equipment or indoor architectural elements. It has chromium and nickel, which provide good general corrosion resistance[^9]. However, it lacks a strong defense against chlorides[^8]. This is where 316L[^3] stainless steel comes in. The “L” stands for “low carbon,” which helps prevent corrosion after welding, but the real hero is the 2-3% molybdenum content. This addition creates a much tougher passive layer on the steel’s surface, specifically to fight off pitting and crevice corrosion[^10] caused by salt. Think of it as a specialized shield. Using 304 by the coast is a gamble that rarely pays off. We insist on 316L[^3] for any project within a few miles of the ocean. It’s a non-negotiable part of our quality promise.

Stainless Steel Grade Comparison for Coastal Use

Feature | 304 Stainless Steel | 316L Stainless Steel |

Primary Use | General Purpose, Indoor | Marine, Chemical Environments |

Chloride Resistance | Low to Moderate | High |

Key Alloying Element | Chromium, Nickel | Chromium, Nickel, Molybdenum |

Long-Term Cost | Lower initial cost, higher maintenance | Higher initial cost, lower maintenance |

Coastal Suitability | Not Recommended | Highly Recommended |

How does smart design prevent a sculpture from failing by the sea?

Even the best material can fail if the design is flawed. Water can get trapped in crevices and joints, creating perfect spots for corrosion to start. Your design must shed water, not hold it.

A smart design for coastal sculptures focuses on eliminating areas where saltwater can pool. This means using smooth, continuous welds, designing integrated drainage channels, and avoiding complex geometries that trap moisture. The structure itself must be engineered to prevent crevice corrosion[^10] from starting.

Material selection is only half the battle. The other half is engineering. Saltwater is relentless, and if you give it a place to sit, it will cause damage. This is a concept called crevice corrosion[^10]. It happens in small, tight spaces where stagnant water can accumulate. The chemical balance in that trapped water changes, becomes more acidic, and starts to eat away at the steel, even 316L[^3] grade. This is why we spend so much time on the engineering drawings before we ever cut a piece of metal. We look for potential trouble spots. Are there any flat surfaces that don’t drain? Are the weld joints[^11] designed to be completely sealed and smooth? Are there hidden areas inside the sculpture where condensation could get trapped? We design subtle, hidden drainage paths to ensure water always has a way out. We also make sure all welds are full-penetration and ground smooth, leaving no tiny gaps for salt to hide in. A well-designed sculpture cleans itself with every rainfall.

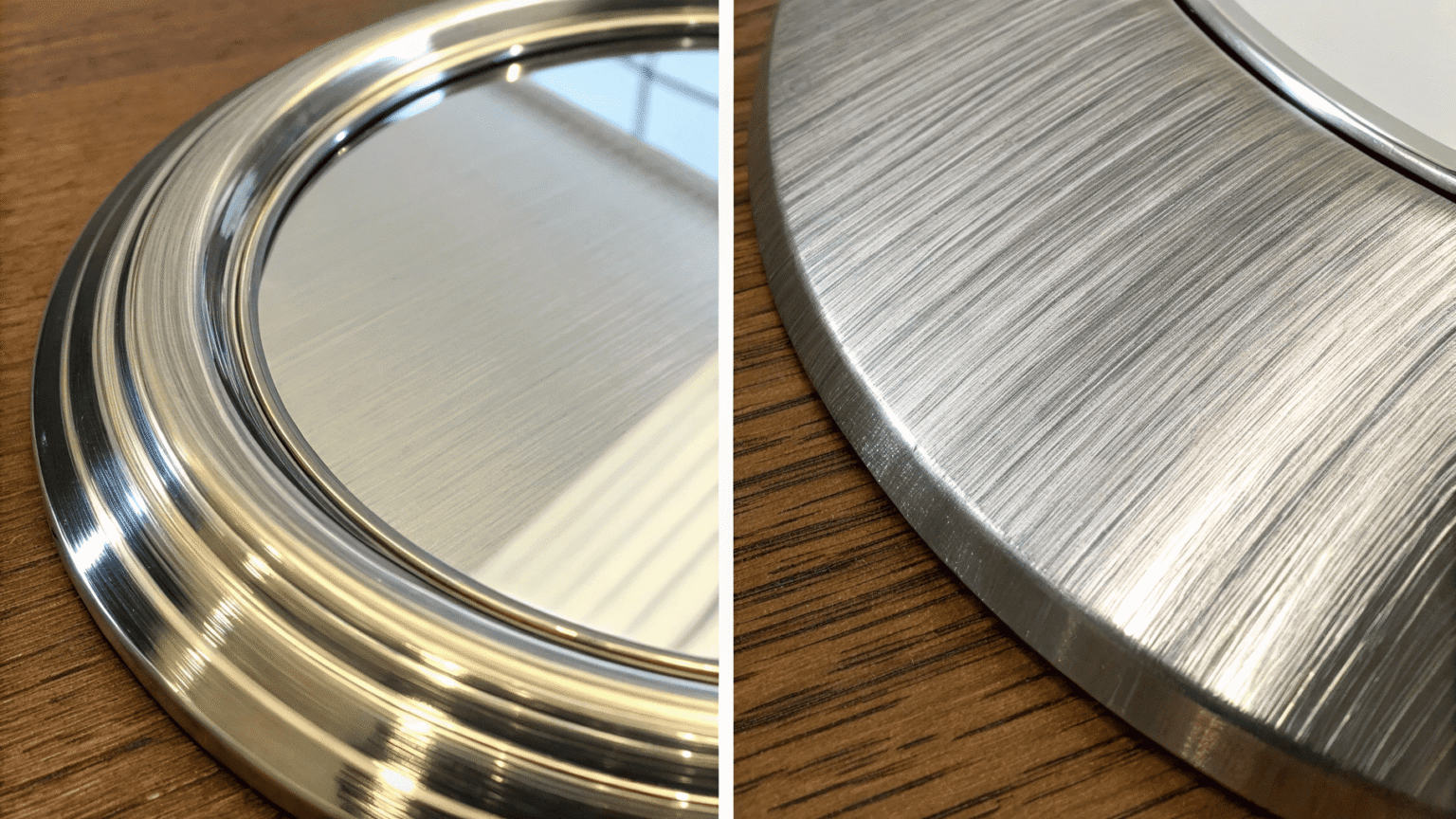

What surface finish best protects a stainless steel sculpture from salt?

The final look of your sculpture also affects its lifespan. A rough or porous surface can trap salt particles, accelerating corrosion. You need a finish that is both beautiful and easy to clean.

A mirror polish[^13] or a fine-grit brushed finish is best for protecting coastal stainless steel sculptures[^1]. These smooth, non-porous surfaces prevent salt and dirt from sticking. They are easy to clean with fresh water, which is the most effective way to maintain the sculpture’s appearance and integrity.

The surface finish[^12] is your sculpture’s first line of defense. Think of it like the paint on a car. A smooth, glossy surface is much easier to wash and keep clean than a rough, matte one. For stainless steel, a mirror polish[^13] is the ultimate finish for a coastal environment. It is so smooth that salt crystals and other corrosive particles have a very difficult time latching on. Rain naturally washes it clean. A fine, directional brushed finish (we recommend a #4 or finer) is also a very good option. The key is that the surface is not coarse or porous. We generally advise against rougher finishes like bead blasting for coastal areas, as the microscopic pits can trap salt. We also recommend a regular maintenance schedule[^14]. It’s simple: just rinse the sculpture with fresh water periodically. This washes away any accumulated salt deposits before they can cause harm. This small step can add decades to the life of the artwork.

Conclusion

So, yes, stainless steel is perfect for the coast. Just be sure to use the right grade, a smart design, and a proper finish. It’s a reliable, long-lasting choice.

[^1]: Explore the advantages of stainless steel sculptures, especially in coastal environments, to ensure longevity and beauty.

[^2]: Learn about marine-grade alloys and their significance in preventing corrosion in coastal sculptures.

[^3]: Discover why 316L stainless steel is preferred for coastal projects due to its superior corrosion resistance.

[^4]: Find out how salt spray impacts metals and why it’s crucial to choose the right materials for coastal sculptures.

[^5]: Explore the effects of high humidity on metal sculptures and how to mitigate potential damage.

[^6]: Explore the significance of structural integrity in outdoor sculptures to ensure safety and longevity.

[^7]: Understand the common causes of structural failure in outdoor sculptures and how to avoid them.

[^8]: Learn about chlorides and their role in accelerating metal corrosion, especially in coastal areas.

[^9]: Understand the importance of corrosion resistance in metal sculptures, especially in harsh environments.

[^10]: Discover what crevice corrosion is and how to design sculptures to prevent it effectively.

[^11]: Discover best practices for weld joints in coastal sculptures to enhance durability and prevent corrosion.

[^12]: Explore the best surface finishes for stainless steel sculptures to enhance their durability and appearance.

[^13]: Learn about the benefits of a mirror polish finish for stainless steel sculptures in coastal environments.

[^14]: Understand the importance of a maintenance schedule for stainless steel sculptures to prolong their life.