Introduction

Choosing a dining table feels simple, but a wrong choice creates daily problems. A table that looks good but doesn’t fit your life is a constant source of frustration.

The best custom dining table is more than just beautiful. It balances size with your room’s flow, prioritizes ergonomic comfort[1], uses durable materials[2], and is built with engineering-grade precision for long-term stability.

I’ve spent years in the furniture business, turning designs into reality for hotels, villas, and commercial projects. I’ve seen firsthand what makes a dining table truly work for a space. It’s rarely just about the look. The real magic is in the details that you don’t see at first glance. These details are what separate a good table from a great one. Let’s break down the four most important facts that will help you choose a table that not only looks perfect but also feels perfect for years to come.

Is a Bigger Dining Table Always Better?

Executing international hospitality and luxury projects involves navigating a web of challenges:

- Complex import/export documentation

- Strict lead times tied to hotel or retail opening schedules

- Differing regional standards and installation conditions

- Risk of product damage or quality inconsistency during transport

- Limited visibility across multiple suppliers

NEXTOP’s one-stop project management system eliminates these obstacles by integrating every process — from concept design to installation supervision — under a unified global framework.

NEXTOP’s Global One-Stop Framework

You dream of a large table for hosting big dinners, but your dining area feels tight. A table that’s too big makes the room feel cramped and movement becomes a chore.

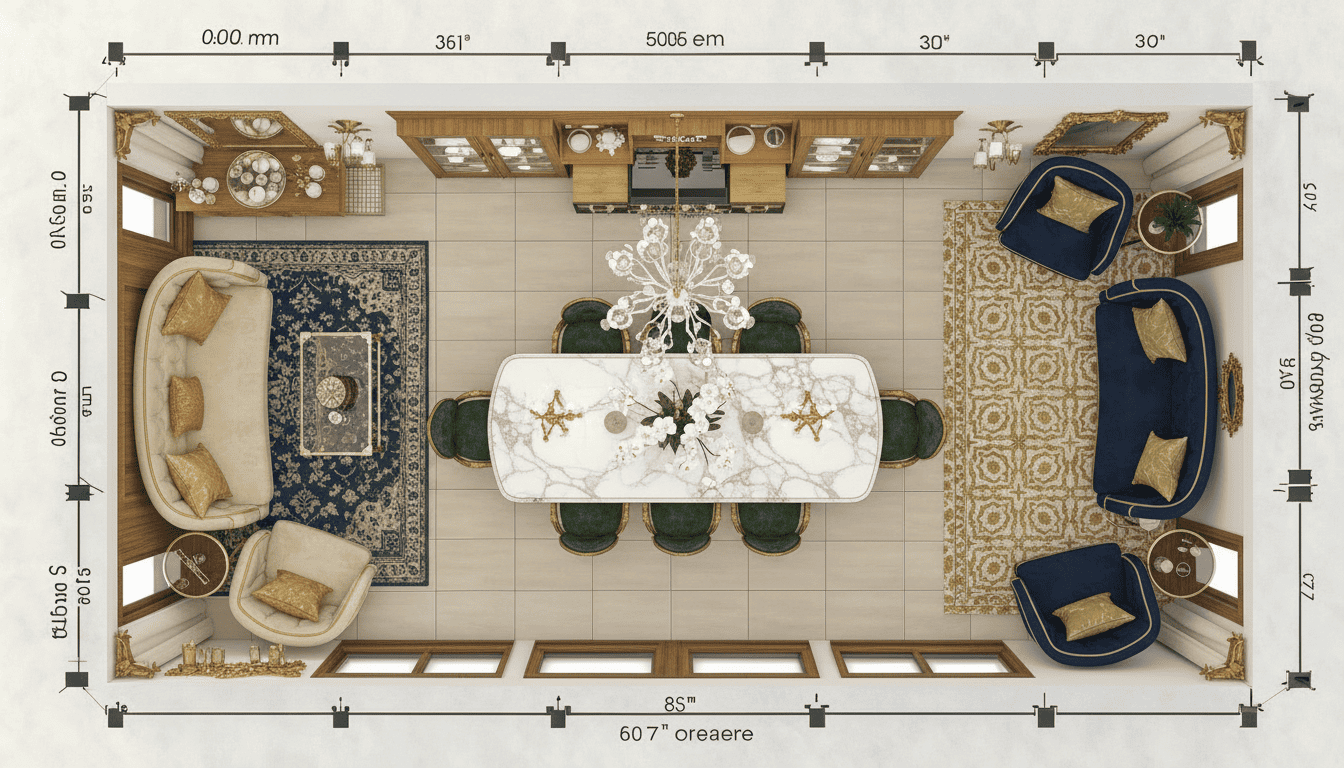

No, a bigger table is not always better. The ideal size balances seating capacity[3] with clearance space[4]. You need at least 36 inches of open space around the table for comfortable movement and pulling out chairs.

When I work with designers on restaurant or hotel suite layouts, the first thing we discuss is flow. We call it “circulation space.” It’s the path people use to walk around the furniture. If that path is blocked, the whole room feels wrong. The same rule applies to your home. You need enough room to walk behind someone who is seated without asking them to move.

The Rule of Thumb for Clearance

A good starting point is to leave at least 36 inches (about 91 cm) of space between the edge of your table and the nearest wall or piece of furniture. If it’s a high-traffic area, like a main walkway, I recommend aiming for 48 inches (about 122 cm). This ensures the space feels open and functional, not cluttered.

Seating Capacity vs. Table Size

Here is a simple guide to help you match the number of seats to the table dimensions[5]. This is crucial for ensuring everyone has enough elbow room.

Seats | Round Table Diameter | Rectangular Table Length |

4 | 36-44 inches | 48 inches |

6 | 44-54 inches | 60-72 inches |

8 | 54-72 inches | 80-96 inches |

10 | 72+ inches | 108-120 inches |

Remember, these are guidelines. With a custom table, we can fine-tune these dimensions to perfectly fit your space and needs.

How Do Ergonomics Affect Your Dining Comfort?

You’ve sat at a table that just felt wrong. Maybe it was too high, or you kept hitting your knees on the legs. These small annoyances can ruin a meal.

Ergonomics are key to dining comfort. This includes the table’s height, the shape of its edges, and especially the placement of its legs. Poor leg placement[6] is a common flaw that causes discomfort.

The most beautiful table in the world is useless if it’s uncomfortable to sit at. I remember a project for a boutique hotel where the initial design had these gorgeous, thick table legs at the corners. But when we built the prototype, we realized that anyone sitting at the ends couldn’t fit their legs comfortably. We had to re-engineer the base to an inset trestle design. The look was slightly different, but the comfort level increased by 100%. The client was thrilled because they understood that guest comfort is paramount. These are the kinds of practical problems we solve every day.

Standard Heights and Why They Matter

The standard height for a dining table is between 29 and 31 inches (74-79 cm). This height is designed to work with standard dining chairs, which usually have a seat height of 18 to 20 inches. This gap allows for comfortable legroom without making you feel like a child at the adult’s table.

The Critical Role of Leg Placement

The position of the table legs directly impacts how many people can sit and how much legroom they have.

- Four Corner Legs:This is a classic style, but it can limit seating at the ends and corners.

- Pedestal Base:A central base is excellent for maximizing legroom and fitting extra chairs around the table. It’s a great solution for round or square tables.

- Trestle Base:Two supports at either end, connected by a beam. This design provides excellent stability and frees up legroom along the sides.

The shape of the tabletop’s edge also matters. A sharp, squared-off edge can be uncomfortable to rest your arms on. We often recommend a slightly rounded or “bullnose” edge, or a beveled “chamfer” edge. These small details make a big difference in the daily experience of using the table.

Why is Material Selection More Than Just Aesthetics?

You see a stunning table, but you worry it will scratch or stain easily. The wrong material can turn your beautiful investment into a source of constant stress and regret.

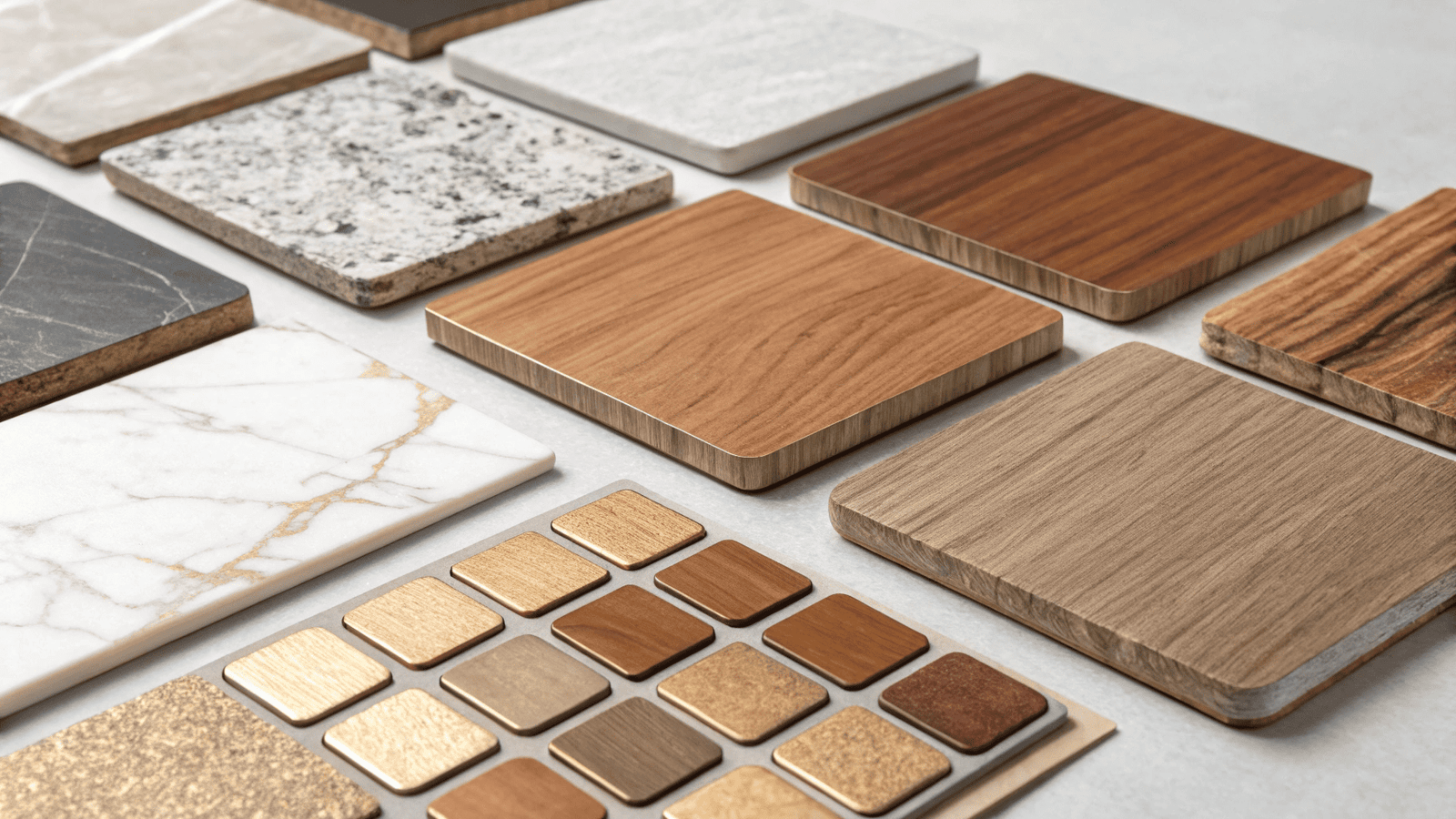

Material choice is critical for a table’s longevity and performance. Solid wood, sintered stone[7], and metal each offer different benefits in terms of durability, heat resistance, and maintenance needs for your specific use.

In my line of work, especially with hospitality clients, a material has to do more than just look good. It has to perform. A restaurant table sees more wear and tear in one month than a home dining table sees in a year. It has to resist scratches, spills, hot plates, and harsh cleaning chemicals. This has taught me to look at materials from a practical, engineering perspective. The right material isn’t just about the look you want today; it’s about how you want the table to look and function five or ten years from now.

Comparing Common Tabletop Materials

Each material has its own set of strengths and weaknesses. The best choice depends on your lifestyle, budget, and how you plan to use the table.

Material | Pros | Cons | Best For |

Solid Wood | Warm, timeless, can be refinished | Can scratch, dent, and is sensitive to moisture | Homes, private dining rooms |

Sintered Stone | Extremely durable, scratch/heat/stain resistant, hygienic | Heavy, can be brittle on impact at edges | Busy families, restaurants, outdoor use |

Veneer | Provides a high-end wood look for less, stable | Cannot be refinished deeply, can chip | Commercial projects, budget-conscious design |

Metal | Very durable, modern aesthetic, flexible design | Can show fingerprints, may feel cold | Industrial-style spaces, table bases |

Choosing the right material is about matching its properties to your needs. For a family with young children, the durability of sintered stone[7] might be the top priority. For a formal dining room, the classic beauty of solid walnut might be the perfect fit.

What Makes a Custom Table Truly "Custom"?

The word “custom” is thrown around a lot. But many companies just offer standard designs in a few different sizes. This isn’t true customization[8], and it often lacks real quality.

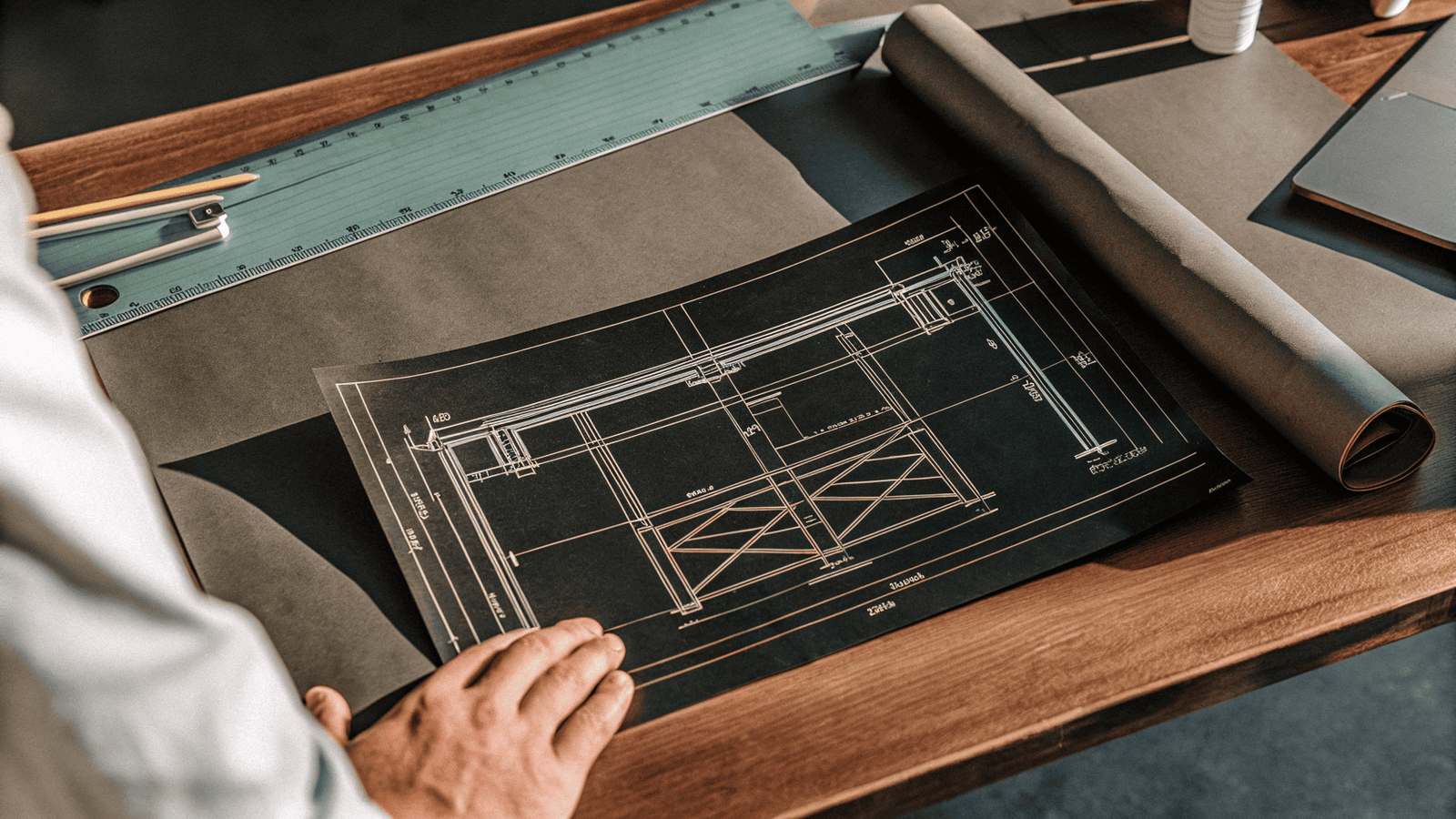

True customization[8] goes far beyond dimensions. It involves professional engineering, from structural reinforcements and high-quality hardware to durable, multi-layer finishes[9]. It’s about building a piece that is stable, strong, and easy to maintain.

I’ve seen a lot of so-called “custom” tables fail over time. A large, beautiful wood tabletop starts to sag in the middle after a year. Why? Because it wasn’t properly reinforced underneath. The builder just scaled up a small design without thinking about physics. At NEXTOP, our process starts with engineering. Before we cut a single piece of wood or metal, we create detailed drawings that plan for structural integrity[10]. We think about how the pieces will connect, what kind of stress the table will endure, and what finish will protect it best. That’s the difference between just making a table to a certain size and truly engineering a custom piece of furniture.

Beyond Dimensions: Structural Integrity

For large tables, especially those made from solid wood, preventing sagging is critical. We often embed steel C-channels into the underside of the tabletop. These channels counteract the wood’s natural tendency to warp or bow over time, keeping the surface perfectly flat. For heavy stone tops, we engineer a robust metal or solid wood sub-frame to provide complete support.

The Unsung Hero: Hardware and Connections

How a table is put together is just as important as the materials it’s made from. We use high-quality bolts and threaded inserts to connect legs and bases. This creates a rock-solid connection that can be tightened over time if needed. It’s a huge step up from the cheap wood screws you find in mass-produced furniture, which can strip and loosen easily.

Finishes That Perform

The finish is your table’s first line of defense. For our commercial projects, we use commercial-grade lacquers[11] and polyurethanes. These are applied in multiple layers in a controlled environment to create a hard, durable shell that resists moisture, stains, and wear. It’s a much more rigorous process than a simple coat of oil or wax, and it ensures the table stays beautiful for years.

Conclusion

A great custom table is a blend of correct sizing, ergonomic comfort[1], durable materials[2], and solid engineering. Understanding these facts helps you create a piece that truly fits your life.

[1]: Learn why ergonomic design is crucial for comfort during meals and how it can improve your dining experience.

[2]: Discover the top materials that ensure longevity and performance for your dining table.

[3]: Find out how to choose the right table size based on your seating needs and space.

[4]: Learn about the necessary clearance for comfortable movement around your dining table.

[5]: Get insights into standard dimensions to help you choose the right table for your space.

[6]: Explore how the placement of table legs can impact comfort and seating capacity.

[7]: Learn why sintered stone is a top choice for durability and maintenance in dining tables.

[8]: Explore the difference between standard and true custom furniture for your home.

[9]: Find out how the right finish can protect your table and keep it looking new.

[10]: Learn how structural integrity ensures the longevity and stability of your dining table.

[11]: Learn about the advantages of using commercial-grade finishes for durability and protection.