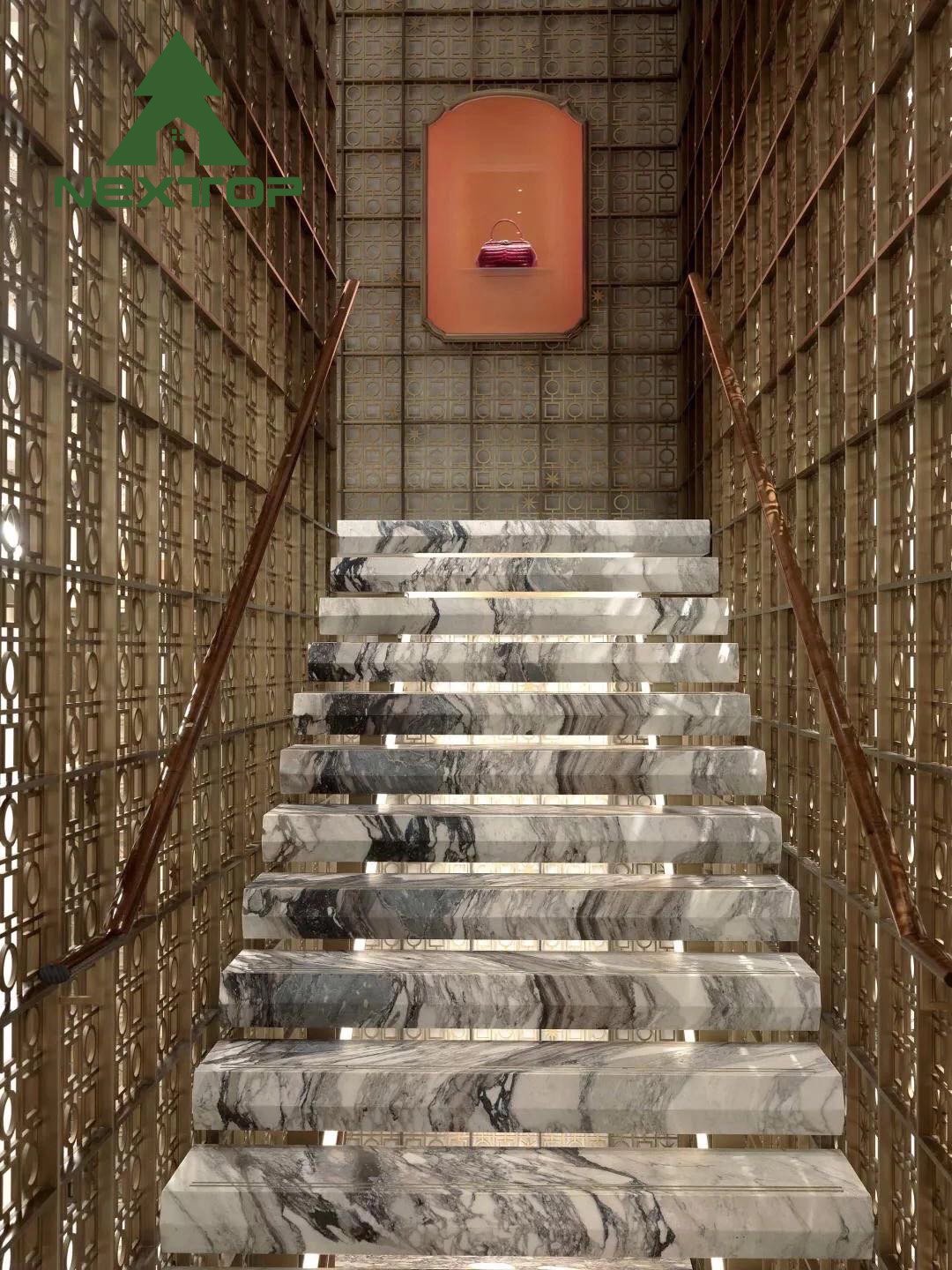

Vietnam Silla Hotel — Stainless Steel Main Gate & Decorative Lobby Screens

Custom Main Gate & Decorative Lobby Screens

Meta Title: Vietnam Silla Hotel — Custom Metal Gate & Lobby Screens | NEXTOP

Meta Description: NEXTOP provided bespoke stainless steel main gate and decorative lobby screens for Vietnam Silla Hotel — precision-engineered, corrosion-resistant, and elegantly finished for luxury hospitality environments.

Project Overview

- Client:Vietnam Silla Hotel

- Category:Architectural Metal Works / Hospitality Fit-Out / Decorative Screens

- Scope:Concept design → structural engineering → precision fabrication → surface finishing → quality inspection → delivery

- Location:Vietnam — Silla Hotel flagship property

- Production Lead Time:60 days from final design approval

Project Background & Objectives

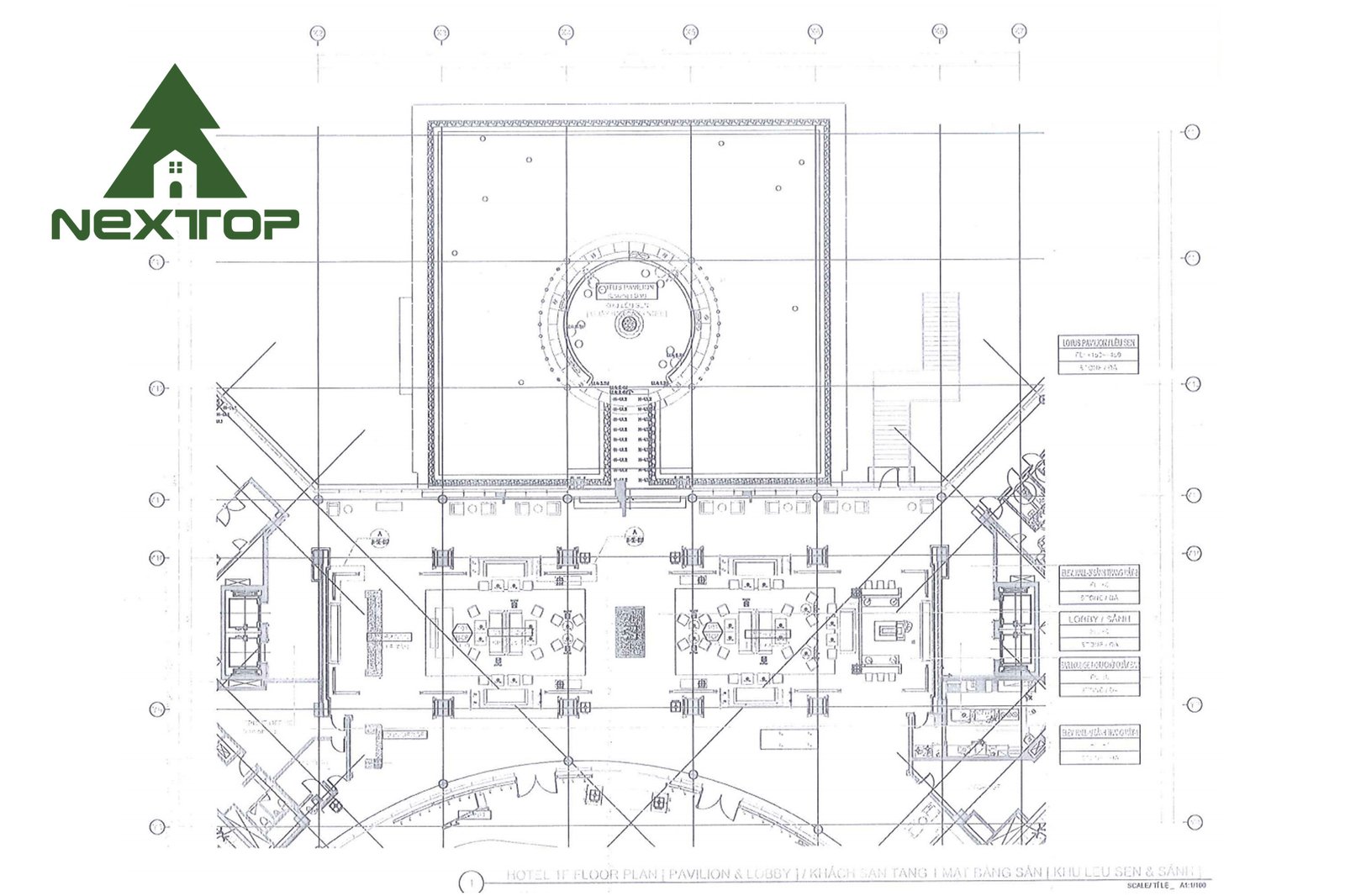

Vietnam Silla Hotel, a landmark luxury property, required distinctive architectural metalwork elements that would elevate both its exterior and interior aesthetics. NEXTOP was selected to design and fabricate:

- A custom stainless-steel main entrance gate, combining security and visual impact.

- A series of decorative lobby screens / partitions, designed to define spaces within the hotel’s grand lobby while maintaining an open and airy ambiance.

Project goals:

1.Reflect the hotel’s modern luxury identitythrough elegant yet functional metalwork.

2.Ensure precision fabricationand superior surface finishing for long-term durability.

3.Deliver all products ready for seamless on-site assemblyby the client’s local team.

4.Maintain consistency between the exterior and interior metal finishesfor visual harmony.

Learn more about our Architectural Metal Works solutions >>

Design & Concept Development

Design Intent

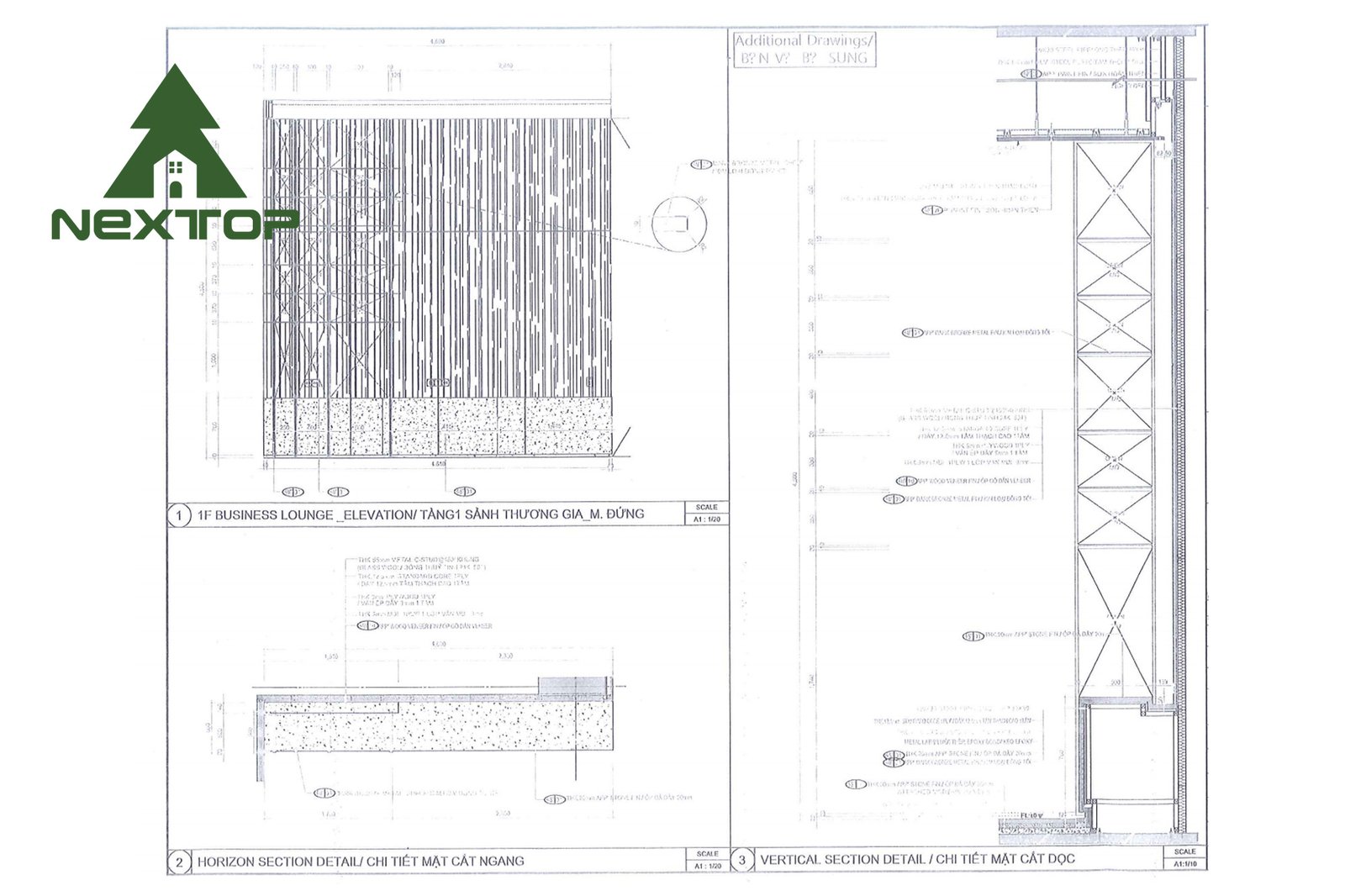

The design concept drew inspiration from modern minimalism, using geometric lattice patterns and balanced proportions to create a visual rhythm between solid and open spaces.

NEXTOP’s design team collaborated closely with the client’s interior designer to ensure pattern continuity and alignment with the hotel’s façade and lobby finishes.

Design Process

1.Initial Consultation & Concept Sketches— developed several design concepts with different geometric motifs.

2.3D Modeling & Visualization— CAD and renderings created to assess scale, lighting interaction, and placement.

3.Material & Finish Samples— provided multiple brushed and mirror-polished stainless-steel swatches for client selection.

4.Final Design Approval— confirmed patterns, frame details, and surface finish type before production.

Engineering & Material Selection

Materials

- Main Gate:Frame and cladding fabricated from Stainless Steel 316, selected for high corrosion resistance and strength in outdoor environments.

- Lobby Screens:Constructed using Stainless Steel 304, offering an excellent balance of formability and surface finish quality.

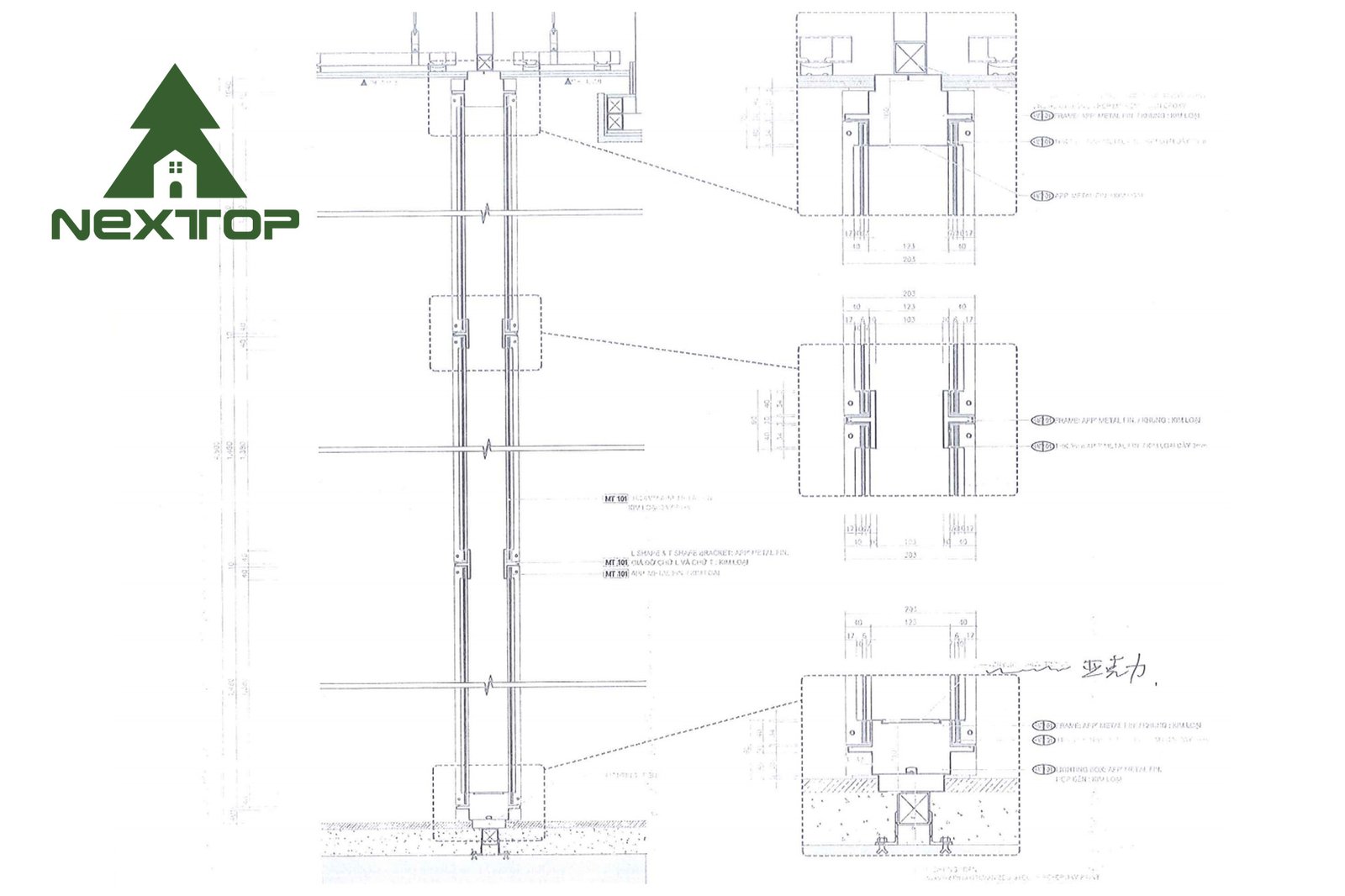

- Fasteners & Support Structures:Hidden stainless steel brackets and frames to maintain a clean appearance and ensure long-term stability.

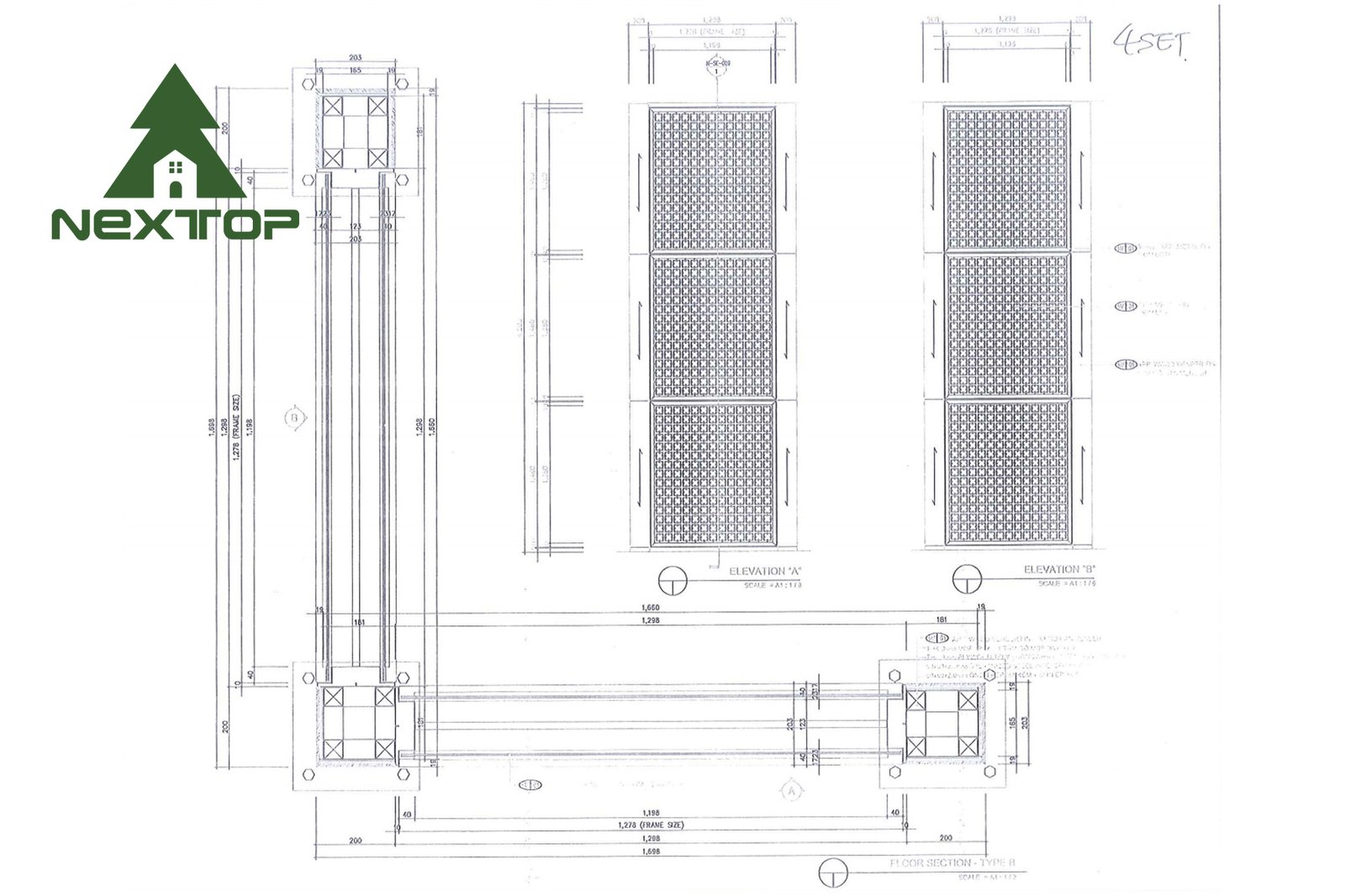

Structural Detailing

- Finite element analysis performed to ensure structural stabilityof large panels under handling and daily operational use.

- Hidden reinforcementintegrated within the main gate structure for rigidity without visible weld lines.

- Modular construction designenabled simplified shipping and on-site assembly by the client’s local contractor.

(More details on finishes and corrosion protection available on our Surface Finishes page >

Fabrication Process — Step by Step

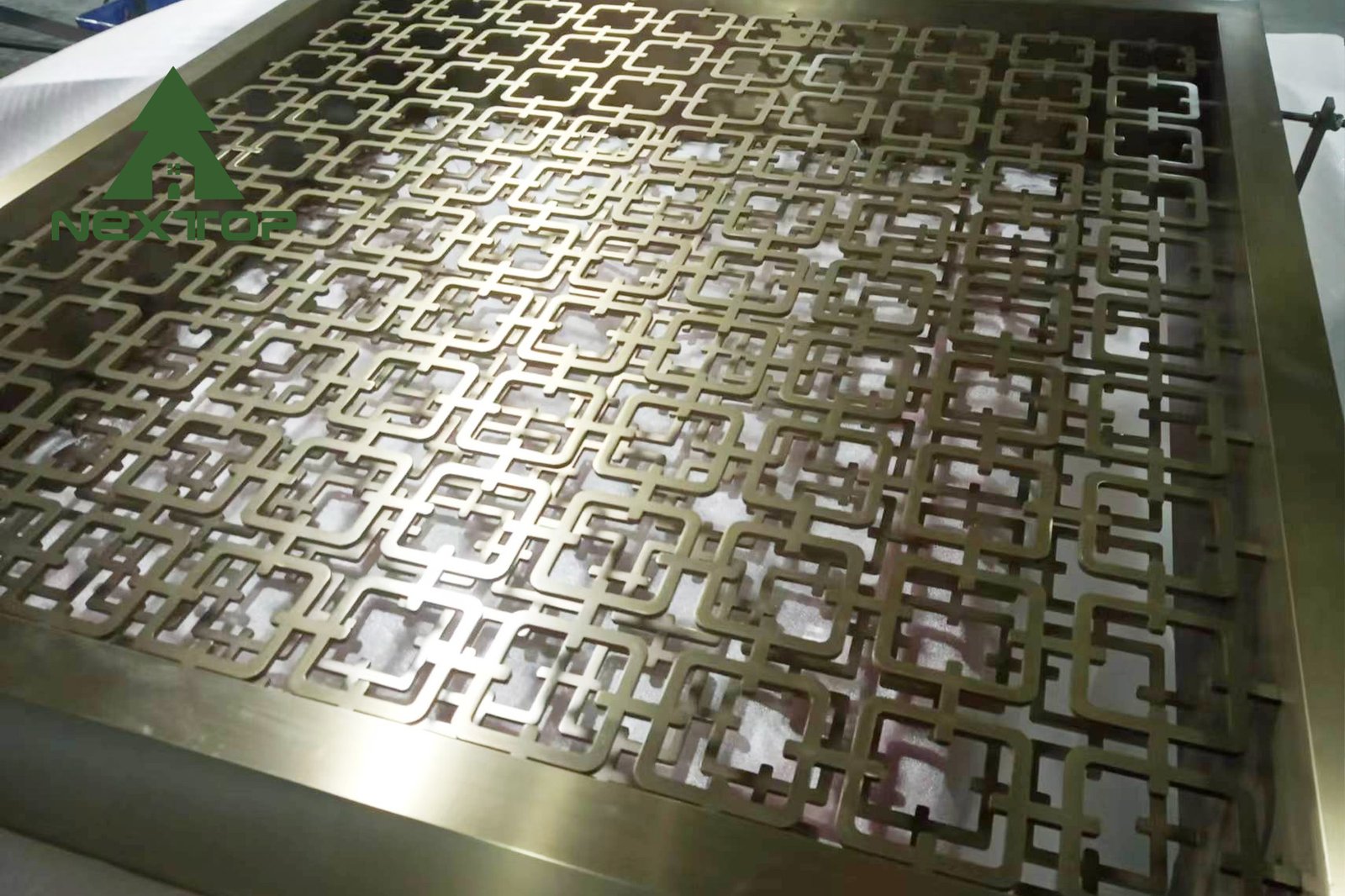

1. CNC Cutting

High-precision fiber laser cutting used to achieve sharp geometric details and consistent edges on stainless-steel sheets.

2. Metal Forming & Assembly

- Precision bending performed on CNC press brakes for frame and edge components.

- TIG welding used throughout to maintain clean, uniform seams with minimal heat distortion.

- Weld joints ground and polished to achieve smooth transitions between components.

3. Surface Preparation & Finishing

- Multi-stage surface treatment, including degreasing, grinding, and passivation to enhance corrosion resistance.

- Final surface finishes:

1.Brushed satin finishfor lobby screens — creating a soft, elegant texture that complements the interior lighting.

2.Mirror-polished finishfor selected gate elements — adding depth and luxury appeal to the façade.

3.Protective coatings applied to prevent fingerprints and improve long-term cleanliness.

4. Quality Inspection & Pre-Delivery Testing

- Dimensional inspection using laser measurement tools.

- Surface gloss uniformity testing.

- Mechanical verification of hinge alignment and frame tolerance.

- Protective packaging design to ensure components arrived in flawless condition.

Learn more about our precision manufacturing process >>

Logistics & Delivery

As the project scope excluded installation, NEXTOP provided ready-to-install components that were pre-assembled and fit-tested in our workshop prior to shipment.

- Each component labeled with detailed installation drawingsfor easy on-site assembly.

- Export packaging used custom wooden crateswith reinforced supports and moisture-proof wrapping.

- All parts delivered with complete documentation, including assembly drawings, maintenance instructions, and finish certification reports.

Learn more about our turnkey supply workflow >>

Project Highlights

- Project:Vietnam Silla Hotel — Main Gate & Decorative Lobby Screens

- Scope:Design, engineering, fabrication, surface finishing, quality control, packaging & delivery

- Materials:Stainless Steel 304 & 316

- Finishes:Brushed Satin and Mirror Polished

- Delivery Time:60 days from final design approval

- Installation:Conducted by client-appointed contractor using NEXTOP’s assembly guide

Aesthetic & Functional Impact

The completed works successfully integrate functionality and artistry, contributing to the hotel’s refined spatial atmosphere:

- The main gateforms a striking first impression, symbolizing exclusivity and craftsmanship.

- The lobby screensprovide elegant spatial division, complementing the marble and lighting scheme.

- The contrast between brushed and mirror surfacesenhances visual depth under both natural and artificial light.

- The consistent stainless-steel palette ensures long-term durability and cohesive brand aesthetics.

Maintenance & Care

NEXTOP provided a detailed care guide to help maintain surface brilliance and prevent corrosion:

- Routine Cleaning:Wipe with microfiber cloth and mild detergent.

- Avoid:Abrasive pads or acid-based cleaners that may damage the stainless-steel finish.

- Periodic Check:Inspect joints and contact points every 6 months for surface wear or scratches.

Why Choose NEXTOP

- Integrated Expertise:From design to fabrication under one roof — ensuring accuracy and consistency.

- Material Mastery:Deep understanding of stainless-steel grades and surface treatment for high-end projects.

- Precision & Quality:Advanced CNC, TIG welding, and polishing techniques ensure flawless results.

- Global Project Experience:Proven track record in luxury hotels, villas, and commercial properties.

- Client-Centric Approach:Flexible collaboration model — from full turnkey solutions to OEM supply and fabrication.

Architectural Metal Works or Fit-Out Solutions for related projects >>

Conclusion

The Vietnam Silla Hotel project demonstrates NEXTOP’s ability to translate design vision into tangible, high-quality metalwork products. From concept to final fabrication, every step was guided by precision, craftsmanship, and a commitment to excellence.

Our stainless-steel main gate and decorative lobby partitions have become signature architectural features that elevate the hotel’s identity and enhance guest experience.

If you are developing a hospitality or commercial project and seek custom architectural metalworks with refined aesthetics and dependable quality

???? Contact NEXTOP today to discuss your design or request a quotation.

Browse Nextop Solutions Full Products

Metal Cladding & Architectural Features

Partitions.Walls. Columns. Ceilings.Sculptures. NEXTOP fabricates stunning architectural metal elements from brushed brass to mirror stainless steel, fully tailored to your shop drawings.

Custom Furniture Production

Built-in cabinets, counters, wardrobes, and bespoke furniture — all manufactured with precision joinery and luxury finishes.

One-Stop Fit-Out Supply

We handle sampling, prototyping, fabrication, packing, and coordination — ready for smooth handover to your installer team on-site.

High-Spec Finishing

RAL powder coating, antique brass patina, PVD coating, vibration patterns — all in-house with strict QC.

Enquiry Form

Contact our Customer Services team by completing the form. We will endeavour to respond within 24 hours.